Success Story – Custom Fin Plates With Thin Material

The Situation

Heat exchangers perform best when fin plate material is thin, extrusions are high, and the plate shape is customized for the application. Those three specs can yield the thermal transfer properties, optimum airflow, and overall performance that heat exchanger designers seek.

But that thin/high/custom-shape combo is difficult to produce. Thin metal can crumple on the press, creating a costly mess. And, punching very high extrusions from thin stock can fail because there’s so little material to work with.

Finally, custom plate shapes are often specified by design engineers, but custom shapes can’t be produced on a standard fin press. These and other considerations can make it difficult to mass-produce custom fin plates with thin material at the lowest possible cost.

The Challenge

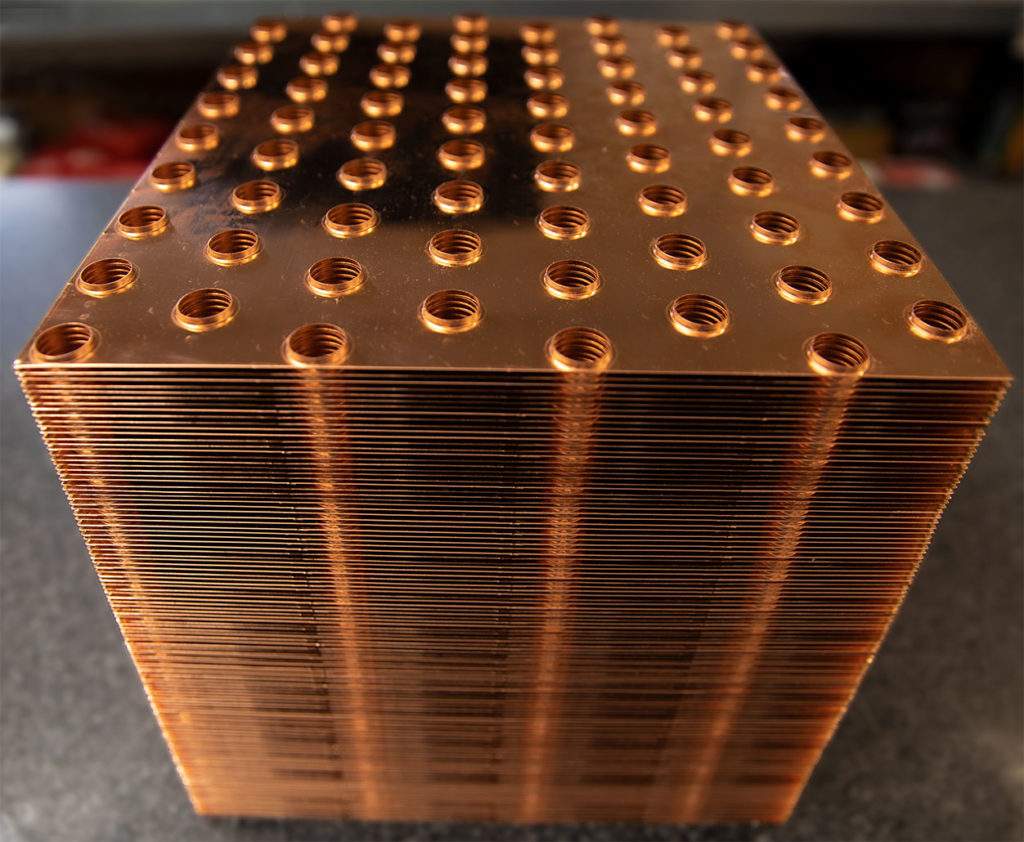

An original equipment manufacturer assigned Ajax to produce custom fin plates for their commercial heat exchangers out of super-thin, 30-gauge (.0127”-.0187”) copper. To achieve the desired fins-per-inch specification, extrusion height would need to be extreme.

Since the OEM designed a custom plate shape to match their innovative, industry-leading design, optimized material nesting would come into play.

As always, only perfect parts could leave the plant. Project costs needed to be very competitive.

The Success

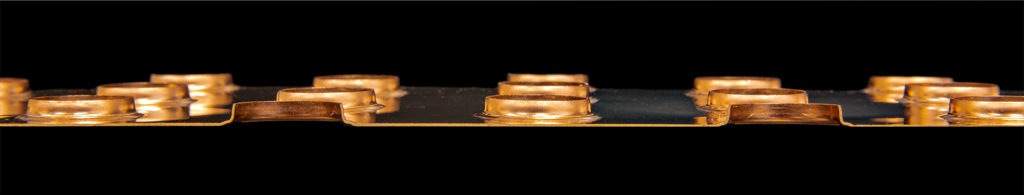

The Ajax engineering team designed a proprietary one-hit process that pierced and formed the extrusions to the perfect height and kept the plate material perfectly flat. The Ajax team used a LVD Strippit V30 CNC turret press to produce the custom shape and so avoided elaborate and expensive tooling often required by standard fin presses.

The end result was a perfectly flat fin plate with very high extrusions that conformed to every customer specification. The one-hit process sped production, shortened the delivery time frame, and minimized costs. Smart material purchasing added to overall project efficiency.

With decades of experience forming custom fin plates, header plates, and casings for HVACR units, Ajax delivers virtually any size and shape using any material.

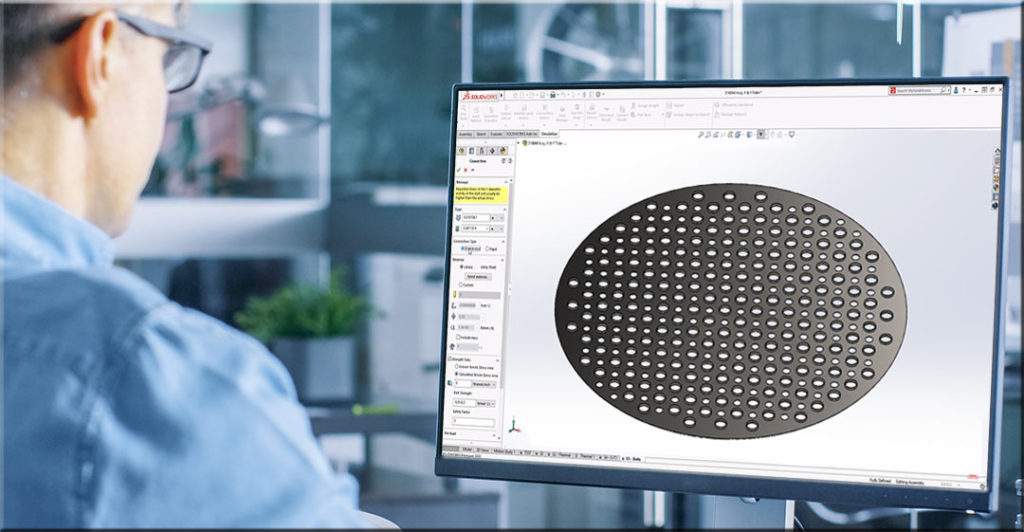

Ajax programmers use design and nesting programs like Solidworks and RADAN to speed production and minimize material waste.

Manufacturing perfectly flat fin plates of thin material is a production challenge that Ajax has overcome.

Note the high, straight extrusions that Ajax tooling and one-hit process can produce.