Heat Exchanger Header Plates

Perfect header plates are a specialty at Ajax

Heat exchangers are a growing HVACR solution for many commercial applications. Heat exchangers are efficient, cost-effective, and versatile. They can fit into smaller spaces, they’re environmentally friendly, they use less energy, and maintenance costs are low.

But there’s a challenge. Heat exchanger header plates can be difficult to manufacture. The plates must be perfectly flat, and the extrusions must be absolutely on spec. Otherwise, the tube insertion process will not go smoothly, increasing production time and risking early system failure should poor fitment go unnoticed.

Heat exchanger header plates (also called tube sheets) have become a specialty here at Ajax. We’ve been forming heat exchanger components for more than two decades now, and we’re good at it. Here’s what makes our header plates so special:

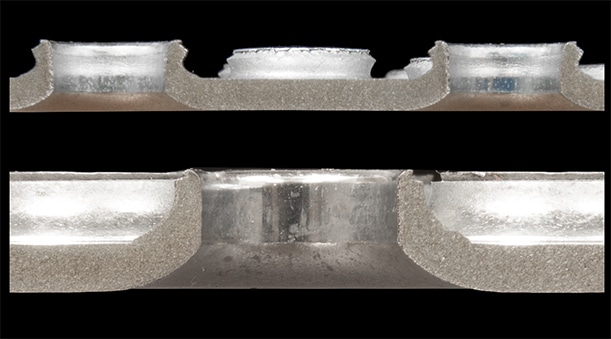

Extrusion Design – Extrusions are one of the keys to making a great tube sheet and a longer-lasting heat exchanger. Ajax extrusions provide more surface contact with the copper or aluminum hairpin tubing that passes through the sheet.

With more surface area in contact with the tube, the hydraulic or mechanical expansion process is far less likely to fail, adding years of life to the installed heat exchanger. This design advantage also helps prevent production line issues that arise when tubes do not fit the extrusions properly.

Tooling – With an in-house tooling department staffed with experts, Ajax can create tooling solutions to fit virtually any specification. Our tooling solutions reduce the number of required hits and therefore keep production costs as low as possible

Machinery – Fully programmable, 30-ton LVD Strippit V-Series turret punch presses that are ideal for HVAC applications such as tube sheets.

Ajax quality standards include careful inspection to make sure our header plates and related parts are in complete compliance.

Other Ajax advantages include:

- State-of-the-art material selection and inventory system.

- Increased capacity following multiple plant capacity and location expansions.

- Our focus on tube sheets enables us to develop our workforce with punch press operation in mind.

- Our press operators are simply better at their jobs because of this focus.

Note the much flatter, straighter walls and tall collar height on this Ajax tube sheet extrusion. Also note how any burrs are directed away from the hole. This difference plays a huge role in the lifespan and performance of a heat exchanger and helps to avoid assembly problems down the line.