In-House Tool & Die Services Can Speed Production and Reduce Costs

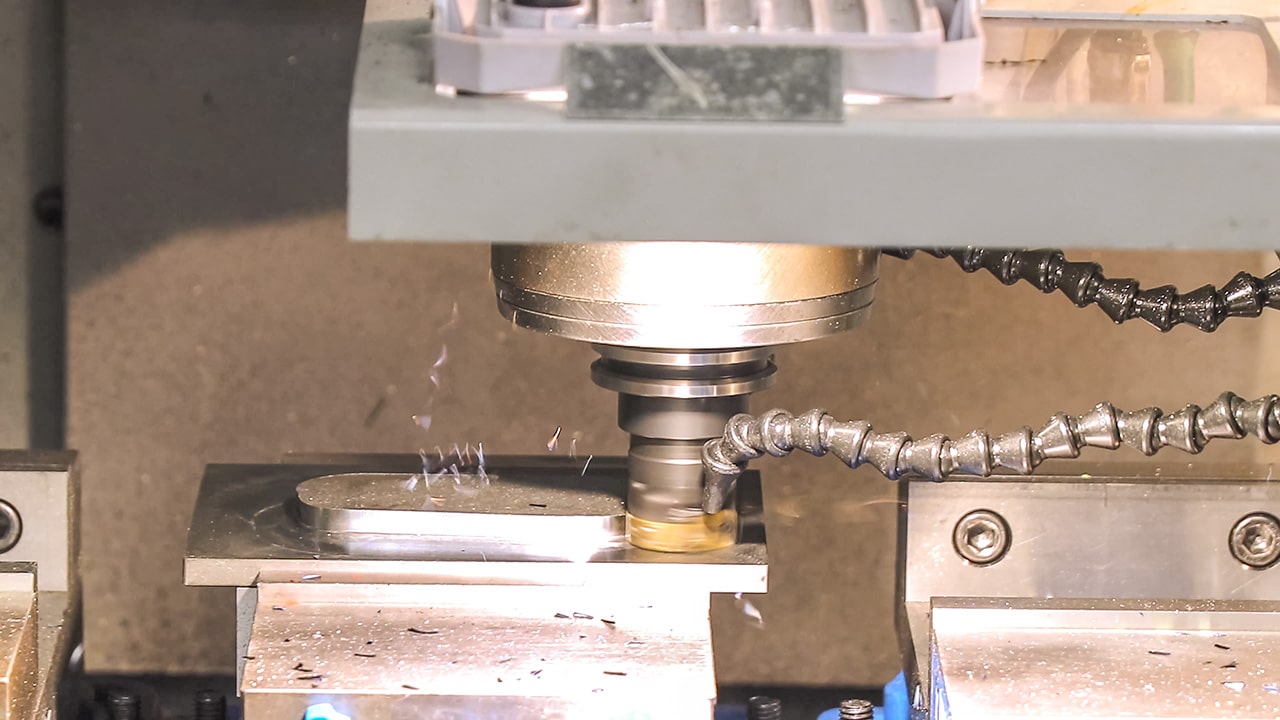

Ajax designs and builds tooling solutions to produce virtually any formed part.In-house Tool and Die Services

By providing complete in-house tool and die services, Ajax gives our customers greater production efficiency, faster delivery, and the best possible quality control. Plus, third-party tooling costs can be avoided.

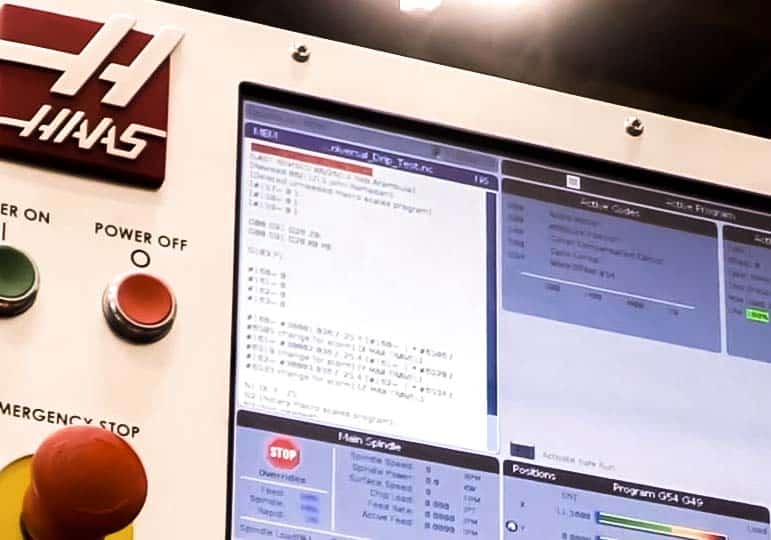

Ajax uses only the latest CAD/CAM technology for die design and tool building. We provide solutions that range from fully progressive, high volume to low-cost, short-run jobs.

We maintain tools on the spot to avoid production interruptions. And we require very thorough training and qualification programs among all our tooling experts.

“Having tooling production right here on our plant floor means that we can keep our lines producing without long delays,” said Ajax Vice President Don Wellman. “We don’t have to send our tooling out to a third party and wait in line. We can get it done here and now.”

Ajax provides tooling storage for customers that require intermittent production. In addition, Ajax is adept at the takeover die process, enabling OEM customers to get their re-shoring parts back into production quickly.

At Ajax, our tool and die sets are produced on-time and on-budget while avoiding third party costs and production or shipping delays. Our experts provide knowledgeable materials procurement coupled with a large in-house material inventory. Kanban scheduling and inventory control optimizes efficiency.