Progressive Stamping At Ajax

Is Progressive Stamping Right For Your Part?Progressive Stamping

Progressive stamping involves the creation of an automated metal forming production line that replaces the manual process of carting partially-completed parts from one production bay to the next. Ajax recommends progressive stamping when:

- High quantities of the same metal part will be needed over a long period of time (a “long-run”), resulting in a lower cost per part

- The cost of more elaborate tooling can be justified

- Multiple cutting and forming operations (“hits”) are required to produce the part efficiently

- Many parts are needed within a short timeframe, forcing quick set-up

- The part must conform to very tight tolerances with few NC (non-conforming) parts

- Higher press tonnage is required to produce the part

Ajax has a long history of engineering stamping solutions that speed production, minimize non-conforming parts, and keep costs as low as possible.

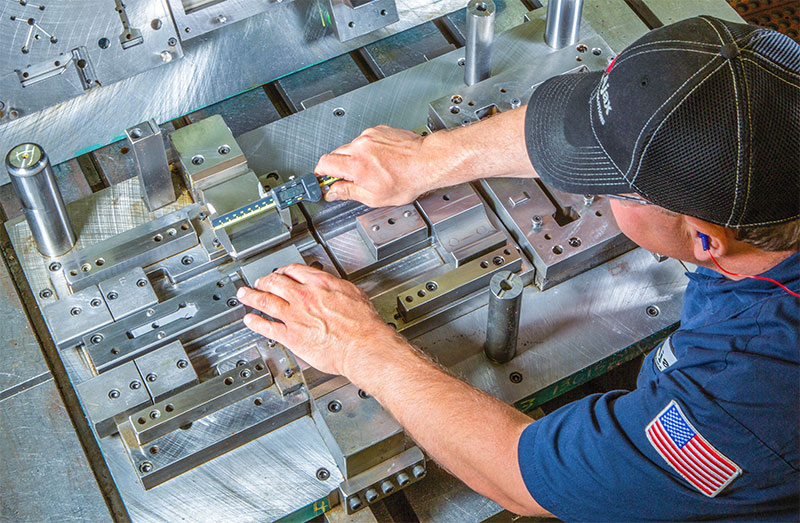

In-House Tooling

The in-house tooling capability at Ajax means we can create, test, maintain and store your stamping tools quickly and cost-effectively. This avoids third-party tooling, which can add significant time and overhead to your project.

Ajax offers the latest tooling technologies and professional expertise for die design and build, such as Logopress3 for SOLIDWORKS™. Solutions range from fully progressive, high volume to low cost, short run.

Our customers get die sets that require very little human interaction during operation, helping to keep labor costs in check. Die-set electronics on every tool improves part quality and prolongs die life.

Here’s a short video showing a progressive stamping tool with hardware insertion.

All Ajax progressive dies employ die-set electronics.