Robotic Welding Explainer Video

This narrated explainer video goes deep into the features and benefits associated with the newest robotic welding tech.

This narrated explainer video goes deep into the features and benefits associated with the newest robotic welding tech.

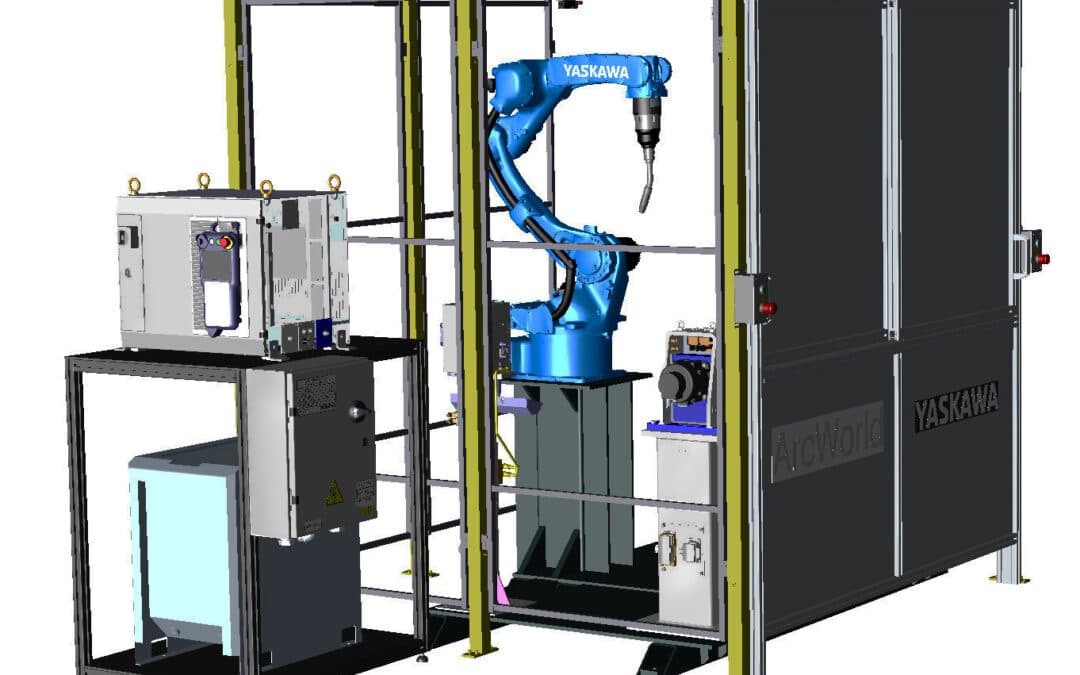

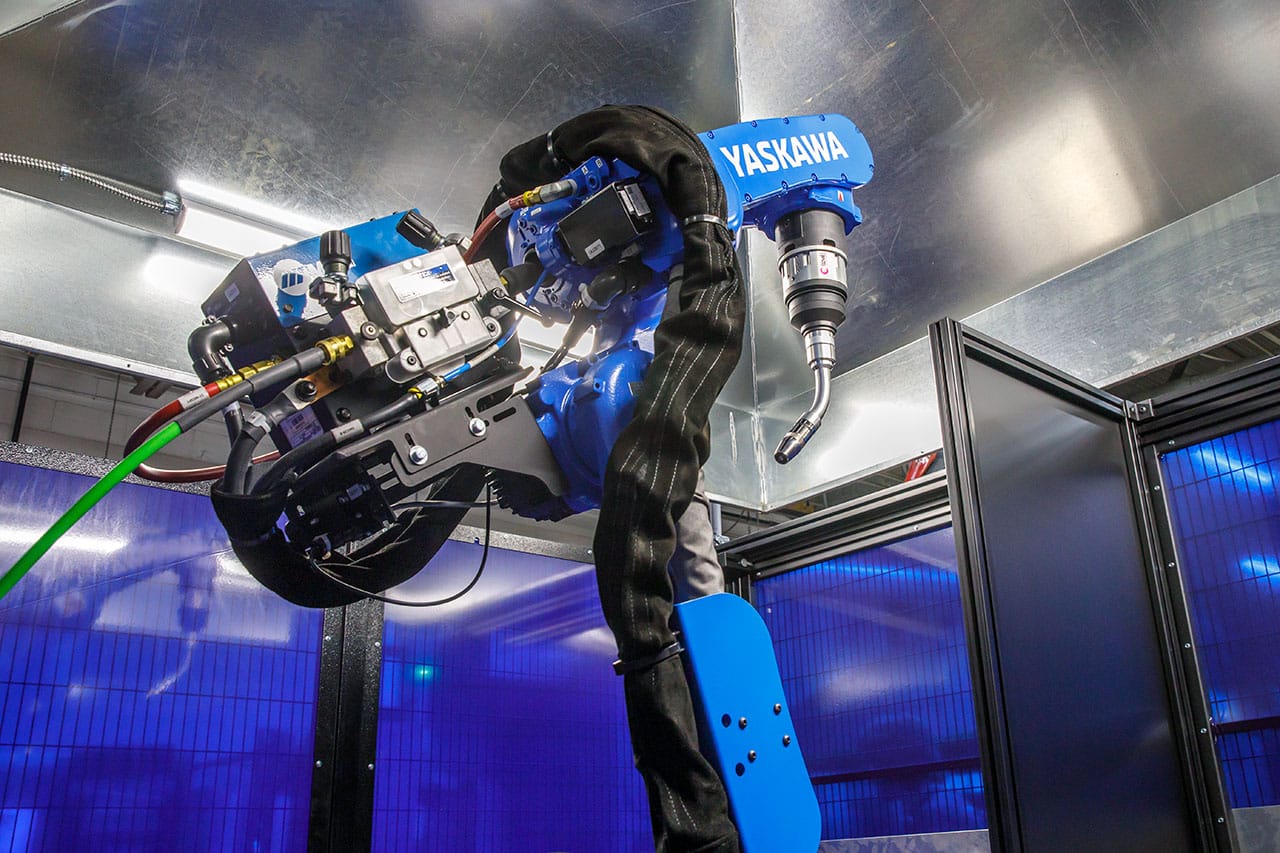

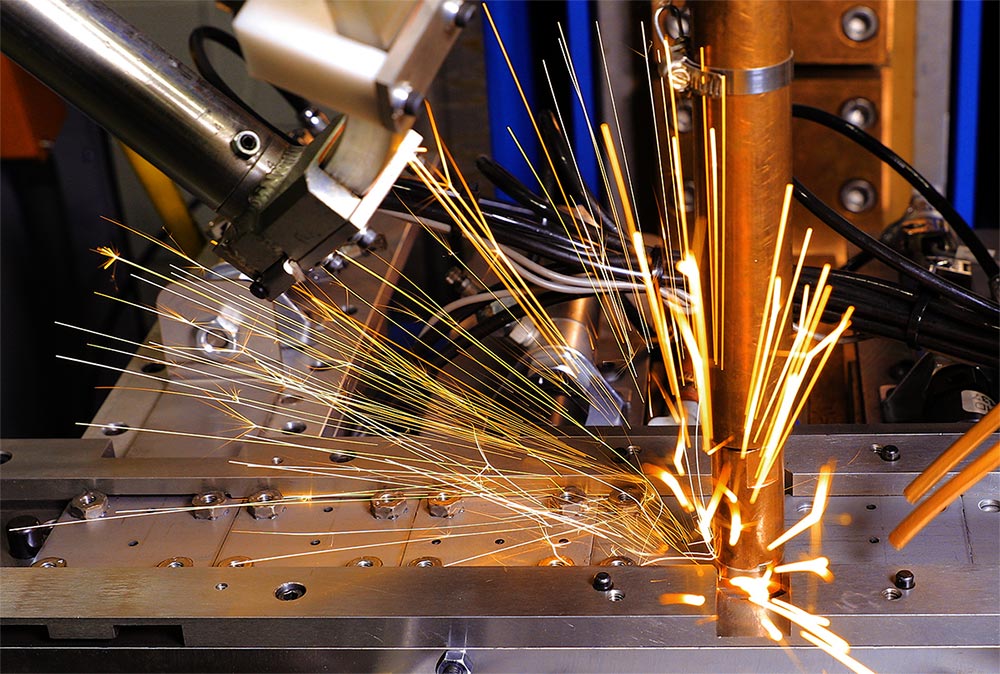

From prototyping to short-run to high-volume, super-efficient lines, robots can handle an extremely broad spectrum of production assignments. Ajax recently installed a Yaskawa AR1440 robot with a welding effector.

This new welding cell enables Ajax to produce high-quality welds efficiently and consistently and will eliminate many of the bottlenecks associated with manual welding operations. Read more on our Welding page.

The Ajax welding cell is a fully enclosed, dual workstation cell with safety interlocking sliding doors. It features a Miller Auto-Continuum MIG power supply for superior weld control, a smart touchscreen teaching pendant, and faster and more efficient offline programming.

From the metal former’s perspective, the benefits of industrial robots are significant and multi-faceted. Primary among them are safety, quality, speed, versatility, and resource allocation. Here’s more detail on each of these benefits:

1. Operator Safety

These days, operator safety is the nut hand*. Many Ajax colleagues have been working together for years and are good friends. No one wants to see a friend get hurt. Robotics can reduce the risk of repetitive motion injury, burn, toxic inhalation, eye damage, and cutting or crushing injury (two thumbs up!). There’s also practical aspects: accidents and injuries can shut down production lines, resulting in late shipments to customers and increased insurance premiums. Anything Ajax can do to reduce that risk is generally worth the expense and effort.

*In poker, the “nut hand” is the strongest possible hand in a given situation and a guaranteed winner. As the story goes, in the old days, a player with such a hand might bet beyond his stake and place the nuts from his wagon wheel on the table, thus assuring other players that he would be unable to flee and would have to make good on his wager.

2. Consistent Quality

Because robotic movements are so precise – generally within 0.02 mm of repeatable accuracy – quality issues are very rare. In fact, it’s far more likely that any non-conformance is related to flaws in materials, fixtures, machine setup, or electrical power interruptions rather than the robotic machinery. Robots make few mistakes, so there’s very little material waste, adding to overall efficiency.

In both production and material handling applications, industrial robots utilize end-of-arm tools (EOATs), also known as end effectors, to hold, manipulate, and perform the work. Robotic effectors, often provided separately by third-party companies, include grippers, magnets, sensors, clamps, suction cups, cameras, welding torches, sanders, and more. The third-party companies that make effectors have come a long way in the past few years and can design their products to take full advantage of the vast range of robotic capabilities.

3. Production Speed

Industrial robots are fast. The volume of parts a robot can crank out in an hour relative to manual production is truly impressive. Even moderately-sized Robotic Weld robots offer thousands of pounds of payload capacity and a reach of 10-20 feet or more. With this kind of range, process improvement engineers can consistently amazing welds. The precise configure robotic solutions that get the job done quickly.

In addition, the fatigue that humans can experience over an eight or ten-hour shift often leads to speed reduction and mistakes. Robots can go at it 24-7 with no performance degradation.

4. Versatility

Industrial robot operating systems are much improved these days, enabling operators to program a wide variety of metal forming tasks. The custom fixtures that hold the workpieces are created in-house, adding to versatility.

Motion controllers, the brains of robots, can be scaled or adapted to meet customer needs relatively quickly. Up to four robots can be added to a single controller to multiply part production. Plus, robots can be programmed to perform multiple jobs in a single setup, reducing project transition times.

5. Operator Assignment

When it’s hard to find good colleagues (like now), robots help shorthanded shifts keep up the pace. A job that might have taken three welders can now be performed by a single robot operator, freeing two workers for other fabrication projects. That’s a huge advantage, especially now.

Conclusion

The manufacturing skills gap persists, despite our best efforts to attract, educate, and grow our manufacturing workforce, making the arrival of industrial robots on the plant floor a welcome sight indeed. Robots bring safety, quality, speed, versatility and other production benefits that are too important to ignore. And for the metal forming customer: consistent conformance, on-time deliveries, and the lowest possible cost.

Yet automation success still hinges on humans. Critical thinking, problem-solving, process engineering, and fine-tuned people skills are needed to amplify the benefits of robots. It’s ironic that industrial automation, often labeled a job-killer in decades past, will instead enhance and extend career opportunities for colleagues willing to learn a new skill set.

Automated production solutions such as industrial robots are a hit because they’re win-win. Both Ajax and our customers will realize the benefits. By investing in industrial robots, and the people we need to engineer and operate them, Ajax is taking yet another big step toward ongoing continuous improvement and maximized customer satisfaction.

Many thanks to our friends at Mechatronic Solutions for their assistance with this robotics project.

We’re Americans. It’s in our nature to want to make things better.

For example, advanced manufacturers like Ajax Metal Forming Solutions have become experts at tight tolerance manufacturing. In this manufacturing environment, the parts the company produces cannot vary more than +/- .002 of an inch. Parts produced to tight tolerances can reduce and even eliminate final product assembly problems. That, in turn, reduces production costs (and headaches).

But let’s be practical. Tight tolerance manufacturing is really all about skilled professionals teaming up to find new ways to exceed customer expectations. More parts in less time, better quality, more consistency, and faster turnaround. That result is measured not in thousandths of an inch, but in happy customers and business growth.

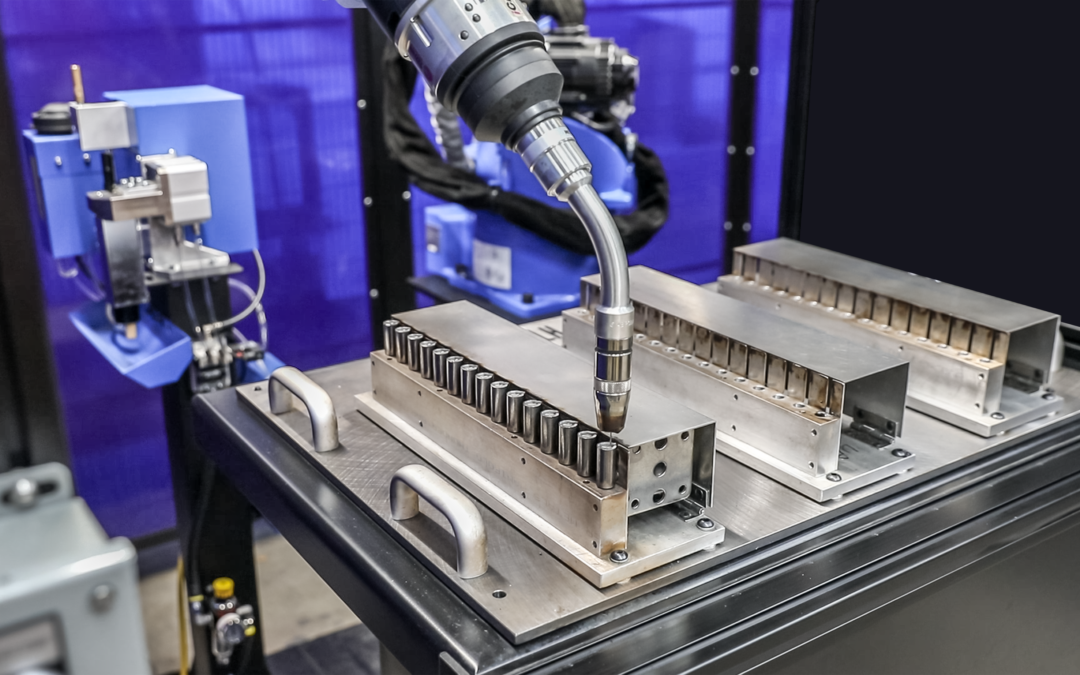

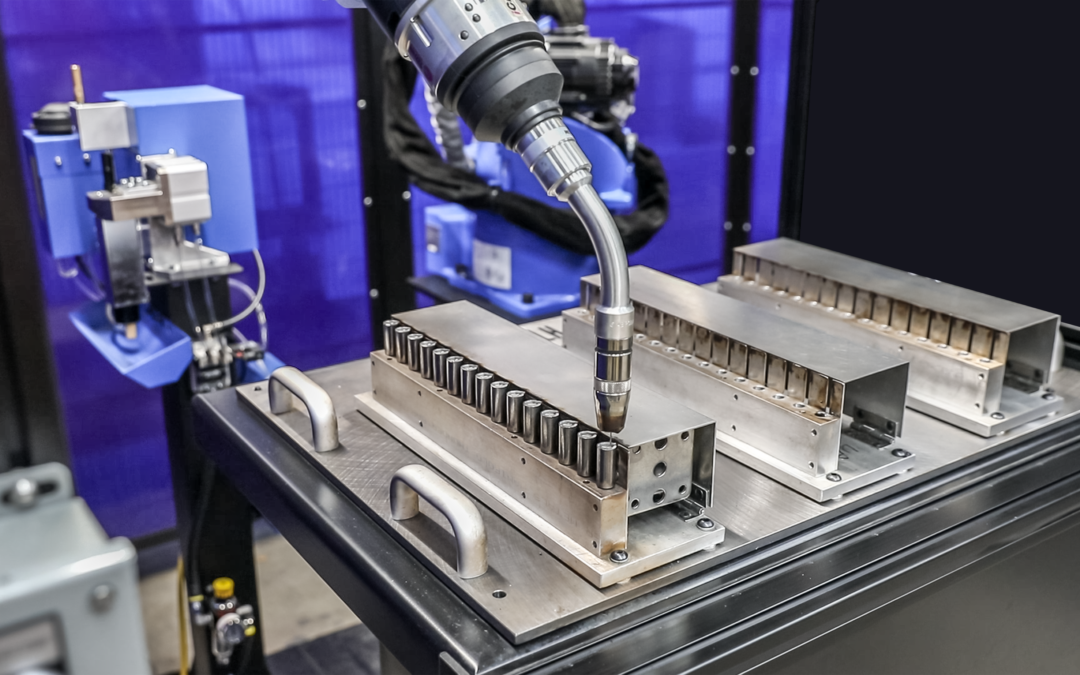

Jayson Marcott, Tool Designer and Sales Engineer at Ajax, was assigned to produce a four-nut backing plate for a refrigeration unit hinge. In this case, the tolerance specification was +/-.005 of True Position. The solution he arrived at is impressive.

Jayson created a pneumatic feed system that can weld four locations on a material blank with only one electrode. This method produces far more parts than could be done manually, and with terrific quality results. A single operator can load material blanks and hardware into individual hoppers, initiate the production cycle, and the tool runs until the hoppers are empty.

“To me, the pilot pin on this tool is what makes it special,” Jayson said. “It can pilot the blank and the nut hardware at the same time before applying weld pressure. If there is. 001 of clearance between the nut and the pilot and the part and the pilot, then we’re at .002 inches of nominal. That’s excellent.”

Jayson designed this tooling solution using SOLIDWORKS CAD/CAE solid modeling software. SOLIDWORKS enables Jayson to create production tools rapidly while bringing creative solutions to bear on any design challenge. Computer simulation capabilities in SOLIDWORKS helps compress the design process and avoid costly delays.

Jayson believes that tooling innovation will be increasingly important as tolerance demands increase over time. “At times in the past, we measured parts that were borderline on tolerance,” Jayson said. “That’s not good enough. With the tooling and other production improvements we’ve made, parts are very close to nominal all the time. Our non-conformance reports these days are minimal.”

This tool needs to be kept in perfect operating condition, and due to the high volume of parts, it requires troubleshooting and a well-trained operator to meet production goals.

Tight tolerance manufacturing tends to affect departments throughout the organization, Jayson said. “We prefer a team approach at Ajax,” he said. “Getting the part right for our customer involves not only tooling, but materials selection, procurement, quality control, and especially customer and team communication.”

Care has to be taken during the initial phases of the project to avoid cost and time frame issues, Jayson said. The benefits of tighter tolerances to the customer are obvious. Customers want their final assembly process to go smoothly with very little assembly fallout. “Costs can get out of line if we hit difficulties along the way. That’s where planning and good team communication comes in.”

Jayson plans to continue pursuing new tooling ideas related to tight tolerance manufacturing. “There’s just no stopping advancements in metal forming,” Jayson said. “Our customers will continue to want more precision in their metal formed parts. The technologies are there. Our job is to learn better ways to apply them.”

Jayson designed this tooling solution using SOLIDWORKS CAD/CAE solid modeling software. SOLIDWORKS enables Jayson to create production tools rapidly while bringing creative solutions to bear on the design challenge. Computer simulation capabilities in SOLIDWORKS help speed the design process along.

Tooling Innovation

Jayson believes that tooling innovation will be increasingly important as tolerance demands increase over time. “At times in the past, we measured parts that were borderline on tolerance,” Jayson said. “That’s not good enough. With the tooling and other production improvements we’ve made, parts are very close to nominal all the time. Our non-conformance reports these days are minimal.”

This tool needs to be kept in perfect operating condition, and due to the high volume of parts, it required troubleshooting and a well-trained operator to meed production goals.

Jayson sums up future manufacturing challenges in two ways: quality and consistency. “There’s really no standing still anymore,” he said. “Today, there’s ongoing market pressure to keep production costs low while improving the delivered result. I don’t see that changing anytime soon.”

Jayson Marcott is a tool designer and sales engineer at Ajax Metal Forming Solutions in Minneapolis, Minnesota. Jayson is certified in SOLIDWORKS, Logopress 3D tool & die design software, aMastercam Mill CNC applications, Methods EDM (electronic discharge) machining. Jayson’s credits also include a Class A 4-year apprenticeship in sheet metal.