Fiber Optic Laser Cutting At Two Locations

Our plants in Minnesota and North Carolina both offer Salvagnini L3 fiber laser cutting.Table Of Contents

- Description of Fiber Optic Laser Cutting

- How Fiber Lasers Work

- Benefits of Nested Files

- Fiber Laser Video

- Adding Deburring To The Process

- Download The Materials Chart

- Getting Your Project Underway

Fiber Optic Laser Description

Fiber optic laser cutting is one of today’s most popular sheet metal fabrication processes. Fiber lasers offer part design flexibility and precision not available through other means.

Ajax was an early adopter of fiber laser cutting capabilities and now offers multiple machines that can accommodate a wide range of materials. Our lasers can cut sheet material up to 5’ x 10’ with thicknesses up to ¾ inch. On light-gauge mild steel, the speed of the fiber laser is up to 2,300 inches/minute. The L3 can cut highly reflective materials, such as high-purity aluminum alloys, brass, and copper, and also coated materials such as galvanized steel.

Materials commonly used for laser cutting include:

- Aluminum

- Beryllium Copper

- Brass

- Phosphor Bronze

- Copper

- Cold Rolled and Hot Rolled Steel

- Galvanized Steel

- Spring Steel

- Stainless Steel

- High Strength Low Alloy (HSLA) Steel

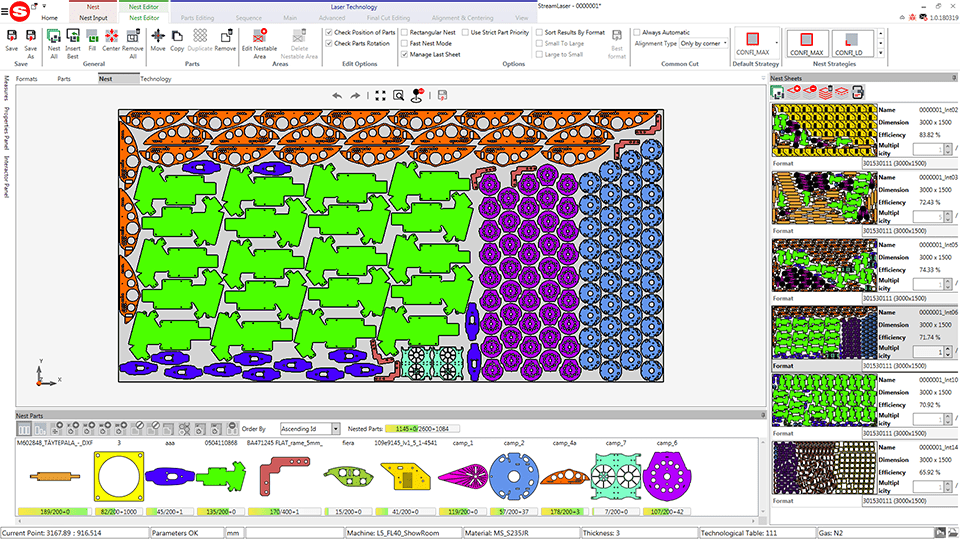

An interior view of one of the Salvagnini L3s at Ajax Metal Forming. The cutting head (inset) is controlled by a computer that increases or decreases the beam intensity and also the position of the beam over the material.

How Fiber Optic Laser Cutting Works

A fiber optic laser cutting machine works by generating a beam of light so thin and so powerful that it can cut through tough metals such as stainless steel quickly and easily. Computers and automated controls are used to precisely position the beam and raise or lower its intensity. A lower intensity beam enables the laser to etch metal, while a higher intensity beam can cut through the metal completely.

The laser’s light is initially created using a bank of light-emitting diodes (LEDs). The machine then “pumps” that light through an amplifier, and then through a fiber optic cable that leads to an automated laser cutting head. The cutting head contains a lens that can focus the light into a super-thin cutting beam.

Many OEMs recognized the benefits of fiber lasers as soon as the technology became practical within a manufacturing environment. The advantages of fiber laser cutting include:

- Extreme precision

- High production speeds

- No-contact cutting prevents scratches

- Fine edge quality

- Computer automation results in maximum quality and productivity

Ajax Metal Forming responded to the soaring demand for fiber laser cutting by investing in fiber laser machinery in 2016. A second Salvagnini L3 fiber laser that was installed in 2018. A third machine was brought online in the Ajax Wilson, North Carolina facility in 2021. More machines are scheduled to be installed in the months and years ahead.

Nesting programs sent through the company network to the laser’s interface enables the laser operator to maximize the number of parts cut from a single sheet of material.

Benefits of Nesting Laser Files

One of the more powerful aspects of laser cutting includes the ability to “nest” custom parts on a large sheet of material. Nesting maximizes the number of finished parts that can be produced from a single sheet and keeps the unit cost of each part as low as possible.

RADAN CAD CAM nesting software is used by skilled Ajax programmers to configure the most efficient nesting pattern for each part. The laser operator then retrieves the nesting files from a secure network location and loads the specified material into the laser’s bed.

To speed production, the computer can “share” nesting file data between multiple lasers on the company’s high-speed network. This enables the operator to quickly shift production from an occupied machine to an available machine. This technique keeps machines operating at maximum efficiency and helps to avoid production bottlenecks.

Fiber Laser Video

This video shows one of our Salvagnini L3 fiber lasers cutting a nested sheet of six panels in less than two minutes. In preparation, the parts are nested in RADAN CAD software. Then the machine runs a sheet location program to align the cutting head precisely. The cutting head then cuts each of the six panels quickly and perfectly. While this sheet is being cut, a second sheet is being loaded onto the machine’s bed. When the cutting program is complete, the finished sheet is ejected, and a new sheet is inserted into the machine so the cycle can repeat. The cut panels go to the Loewer deburring machine or are manually deburred.

Adding Deburring To Fiber Optic Laser Cutting

As the high-intensity fiber optic laser beam cuts through the metal, tiny burrs can accumulate around the cut edges. To remove these burrs, Ajax uses a new Loewer Beltmaster deburring machine. Cut parts are placed on a flexible conveyor that moves the laser-cut parts under an abrasive belt unit followed by two oscillating discs.

The belt and discs polish off the burrs, perfect the edges, and remove any surface imperfections from the laser-cut part. As with most modern metal forming machinery, the Beltmaster is precisely controlled by computer automation.

Today’s new deburring machinery, such as this Loewer Beltmaster at Ajax, will output laser-cut parts with perfect edges and clean surfaces.

Through computer-controlled deburring automation, laser-cut parts at Ajax undergo just the right amount of abrasion. The customer gets perfect parts every time.

Download the Ajax Fiber Optic Laser Cutting Material Guage Chart.

Use this chart to help you determine the material specifications available for Ajax fiber lasers.