Custom Fins for Heat Exchangers

Ajax specializes in custom fins for heat exchangers. We've developed a level of expertise that's second to none.Ajax offers a proprietary manufacturing process that gives custom fin design engineers more options.

Heat exchangers perform best when fin plate material is thin, extrusions are high, and the plate shape is customized for the application. Those three specs can yield the thermal transfer properties, optimum airflow, and overall performance that heat exchanger designers seek.

But that thin/high/custom-shape combo is difficult to produce. Thin material can crumple on the press, creating a costly mess. It’s very challenging to punch high extrusions from thin stock because there’s so little material to work with. In addition, custom shapes can’t be produced on a standard fin press.

Ajax has this problem figured out. The Ajax engineering team has designed a proprietary one-hit process that can form custom shapes, pierce extrusions to the perfect height, and keep plates perfectly flat. All on a CNC turret press that does not require the elaborate and expensive tooling of a standard fin press.

Scaled To Fit Custom Production Needs

Ajax custom fins are manufactured from stainless, copper, and aluminum to virtually any specification. Ajax can do short-run, quick turnaround projects as well as high-volume, high-efficiency production runs.

Ajax in-house engineering and machine operators are fully capable, fully trained, and ready to get your parts into production. Ajax can make almost any size extrusion to fit perfectly with your tube expansion process and equipment, whether it is hydraulic expansion or mechanical expansion.

Programming Expertise

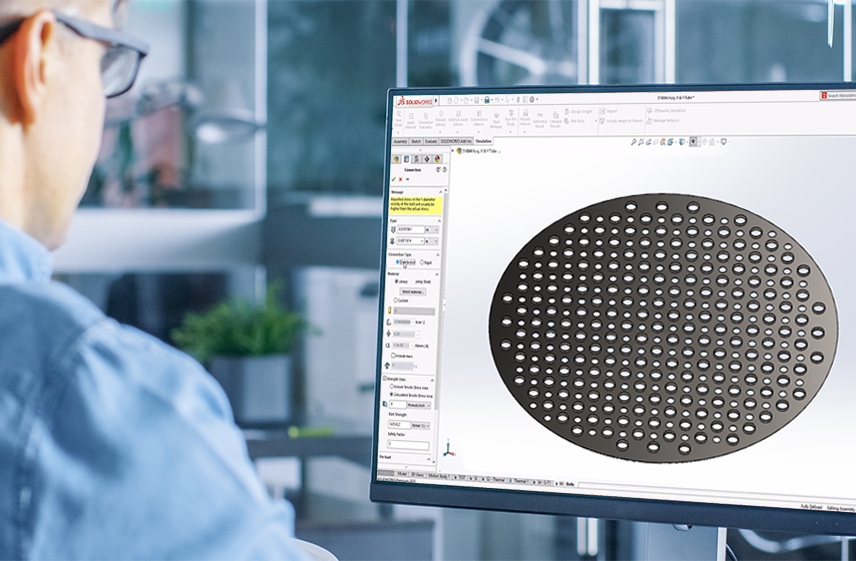

Ajax uses PC-based applications like SolidWorks® 3D CAD, RADAN, and others to compress timelines, improve part quality and improve production efficiency.

These apps are especially useful for nesting custom parts like fin plates and for programming extrusions.

This short video shows how the Ajax one-hit process yields high productivity and perfectly-formed extrusions.

Talk To An Experienced Pro

When you contact Ajax to assist with your fin plate production, you’ll be dealing with a team that really understands thermal technologies. That’s one reason why some of the world’s largest HVACR companies choose Ajax to deliver consistent part quality every time.