Agricultural Equipment Metal Forming

Ajax provides a suite of innovative metal forming solutions that are ideal for agricultural equipment manufacturers.

What parts can we form for your business?

Examples:

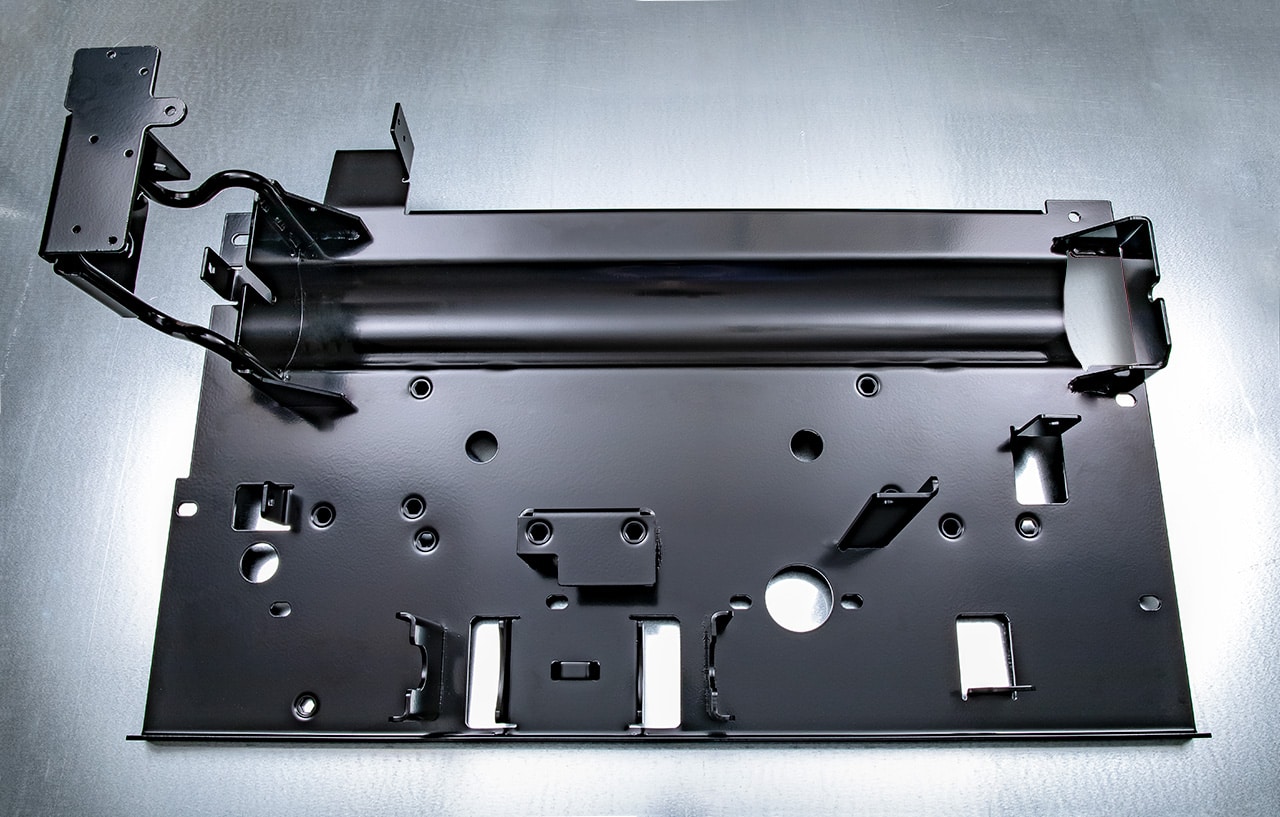

Enclosures & Assemblies

From sheet metal fabrication to stamping to assembly to paint, Ajax metalforming pros can produce mobile enclosures, control panels, doors & hinges, and more. Check out this parts array.

Weldments

Ajax provides TIG, MIG, Spot, and robotic solutions to meet any welding need an ag OEM may have. Plus, Ajax is a practitioner of value engineering to maximize quality and cost-efficiency on every project. Here’s more about Ajax welding capabilities.

Metal Stampings

Metal stamping, especially progressive stamping, can produce parts cost-effectively. Hardware insertion, deep draw stamping and servo forming are specific areas of expertise at Ajax.

State Of The Art Machinery

Ajax has boldly invested in new machinery despite a tide of global economic uncertainty. That’s one way we remain highly competitive in all facets of metal forming. Plus, Ajax added a second plant location to handle more workload and stay closer to our valued customers. For these and other reasons, Ajax makes a great partner for agricultural equipment manufacturers.

CNC Turret Punch Press

Turret press tooling and operation are specific areas of differentiation for Ajax. We’ve perfected the “one-hit” extrusion process that greatly reduces cost and material, while at the same time producing a perfect result. More here.

14 Foot Press Brake

Partner with Ajax Metal Forming and AutoForm+ and you’ll get the best of everything: 14-foot capacity, precision, speed, versatility, consistency, and efficiency: ideal for agricultural equipment part production. Here are the details.

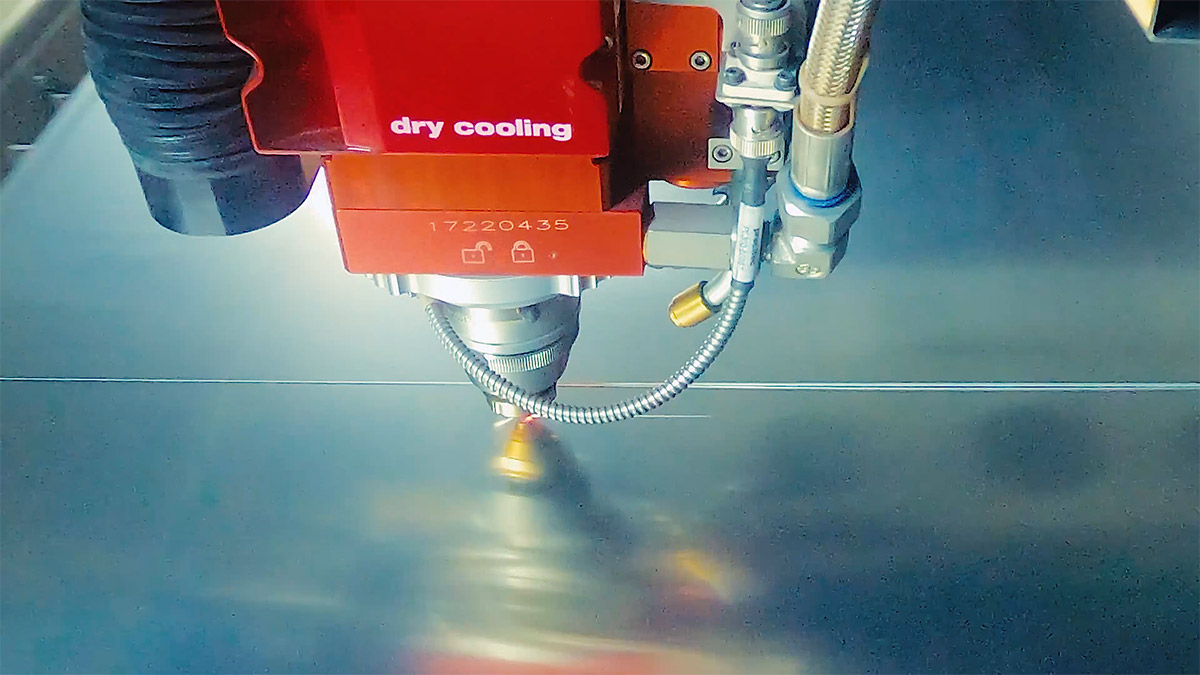

Fiber Optic Laser

In late 2013, when the Ajax team ordered the company’s first Salvagnini L3 fiber optic laser, we suspected it could become a fairly busy machine. Today, we couldn’t do without fiber laser cutting; it’s become standard equipment. We network them to reduce bottlenecks. Here’s a look at the inside of a new one.

Industrial Robotic Welder

From prototyping to short-run to high-volume, super-efficient lines, robots can handle an extremely broad spectrum of production assignments. The Ajax Yaskawa AR1440 welding robot makes clean, precise welds and is extremely productive, helping to keep costs as low as possible.

This animation shows how the new Ajax robot will operate. Note how the robot can automatically clean the welding effector and then move on to the next welding project. This self-cleaning capability is one of the keys to the robot’s efficiency.

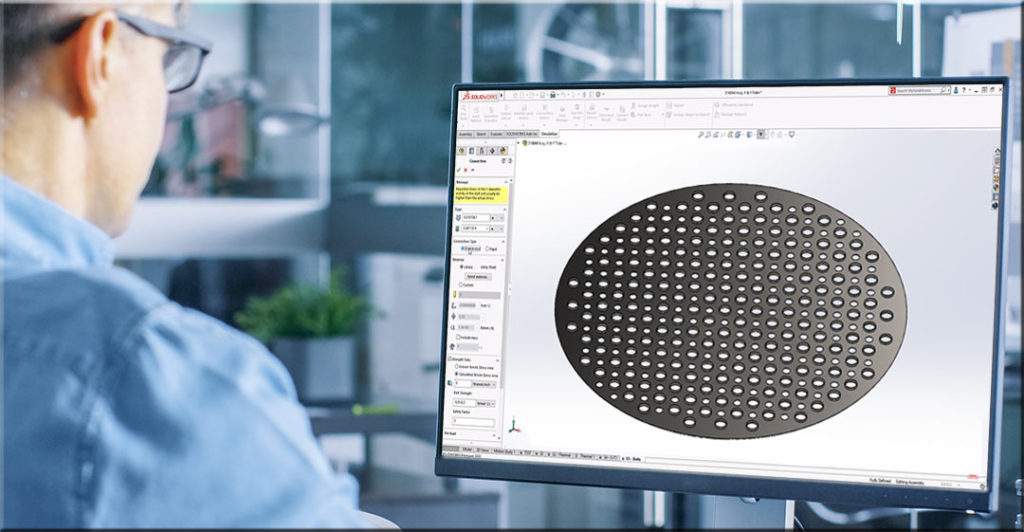

Expert Services That Make a Big Difference

Agricultural equipment OEMs are in a hotly competitive market. Their expectations for metal forming partners include precision, consistency, and highly-competent part programming. Ajax delivers on all these counts, including expertise with SOLIDWORKS® and RADAN CAD CAM software applications.

Quality Assurance

These days, the “quality” marketing message is so common and ubiquitous that not many people pay attention to the words anymore. Sure, all metal forming companies claim a superior quality record. But that message won’t stick to the ear of a savvy customer unless backed by credible facts that justify the boast. Ajax has a solution. Read it here.

Value Engineering

Everybody in the metal forming business wants to get better at what they do. No one wants to see their company fall behind or lose customers to a competitor. We at Ajax just take that idea a little more seriously than most. That’s why we apply Value Engineering. Learn more here.

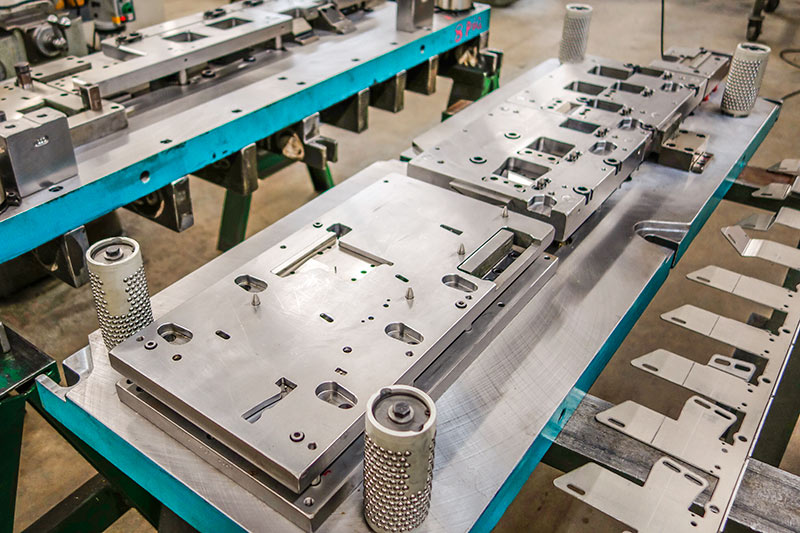

By providing complete in-house tool and die services, Ajax gives our customers greater production efficiency and the best possible quality control. Plus, third-party tooling costs can be avoided. And you won’t have to wait 6 months for your tool to be delivered. Get the story here.