History of Ajax Metal Forming Solutions

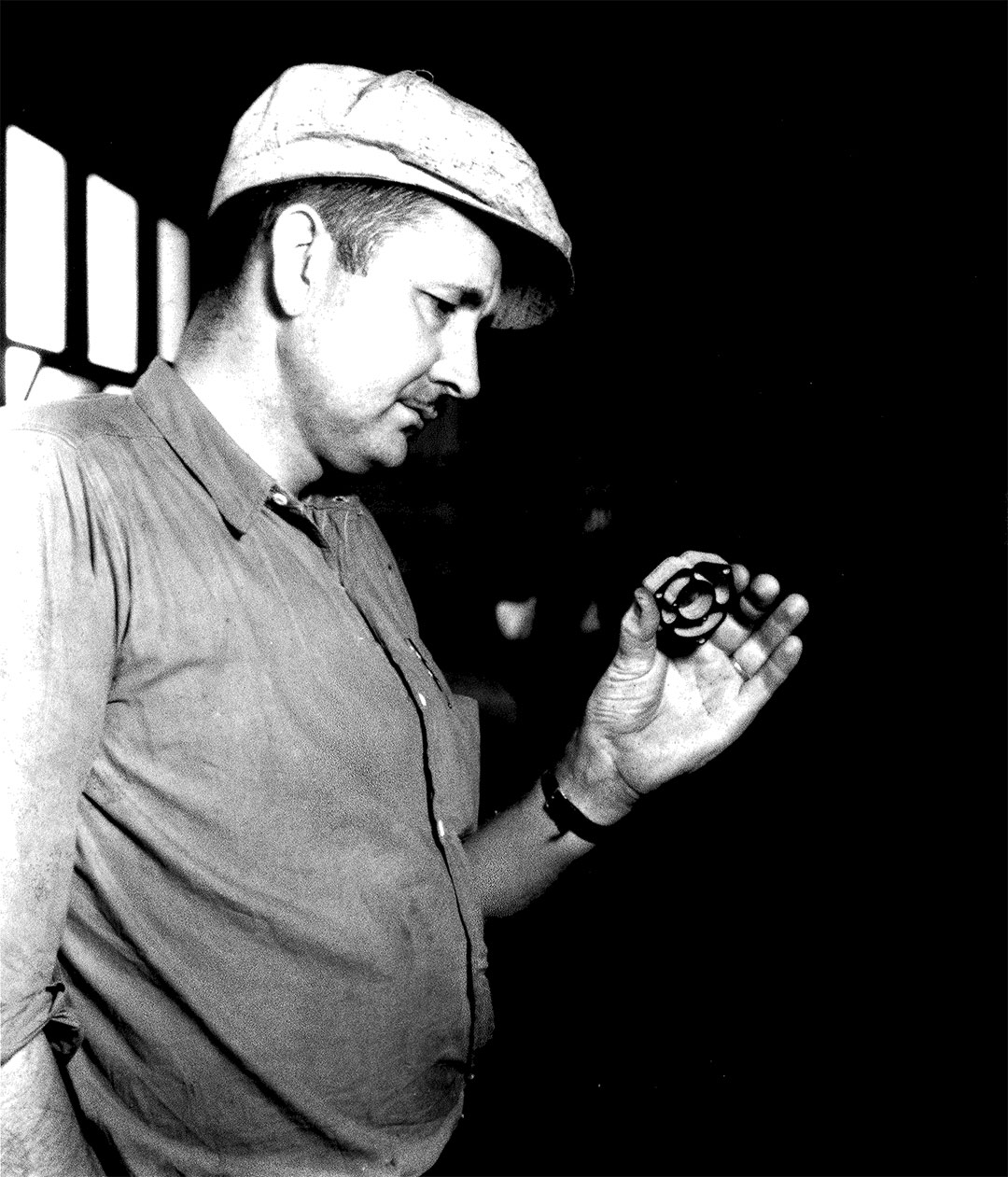

The company now known as Ajax Metal Forming Solutions was founded in Minneapolis, Minnesota in 1945 by Swedish immigrant and inventor Erick Julius Ajax. Erick was a skilled machinist with an entrepreneurial spirit who received several U.S. patents for his product ideas. Providing machine shop services out of his basement, then later out of a 6,000 square foot space in the Northtown train yards in Minneapolis, Erick was joined by his sons Wallace “Bud” and Warren Ajax. Together they operated the company as E.J. Ajax & Sons.

Ajax has come a long way in the past three-quarters of a century. Today, the company is a thriving advanced manufacturer with two locations and 90 employees. The company provides metal forming services for smaller manufacturers as well as leading fortune 1000 industrial corporations in industries such as HVAC, appliances, architecture, commercial and residential construction, automotive, medical, and others.

Below is a timeline of significant events in the history of Ajax Metal Forming Solutions. Click any image to enlarge.

Ajax Company Timeline

1945 – The history of Ajax begins following the end of WWII, when Swedish inventor Erick Julius Ajax began providing machine shop services out of his Minneapolis basement and building tools and dies to manufacture his product ideas.

1946 to 1982 – The company began to grow, relocating to a Washington Avenue storefront and later a 4,000 square foot basement on 10th Avenue in Minneapolis, then a 6,000 square foot shop in Fridley, Minnesota.

Along with sons Wallace and Warren Ajax, Erick manufactured consumer products such as the Ajax Doz-All fishing knife and the E.J. Ajax garment hanger, sold through Sears, Robuck and Co.

Following Erick Julius’ death in 1948, the brothers owned and operated the company for 37 years.

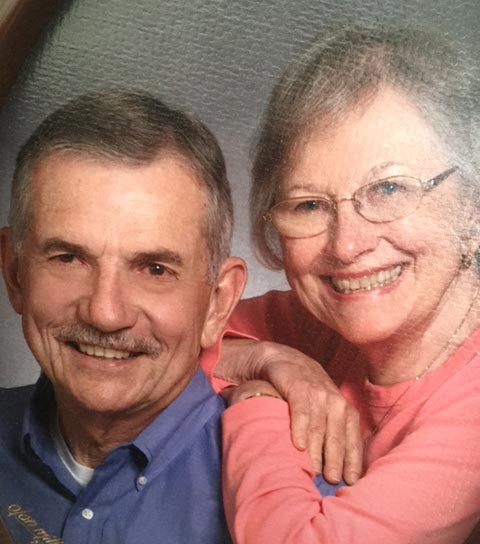

1982 – Younger Ajax brother Sheldon and his wife Barbara purchase the company from Wallace and Warren. The couple operate Ajax for 15 years, overseeing a period of significant growth that included a move to the current location at 7773 Ranchers Road NE in Fridley, Minnesota.

The note to purchase the company from Wallace and Warren was burdensome, but Sheldon and Barbara were able to finally retire the loan in ten years.

Son David Ajax joins the company and becomes an accomplished Journeyman tool and die maker.

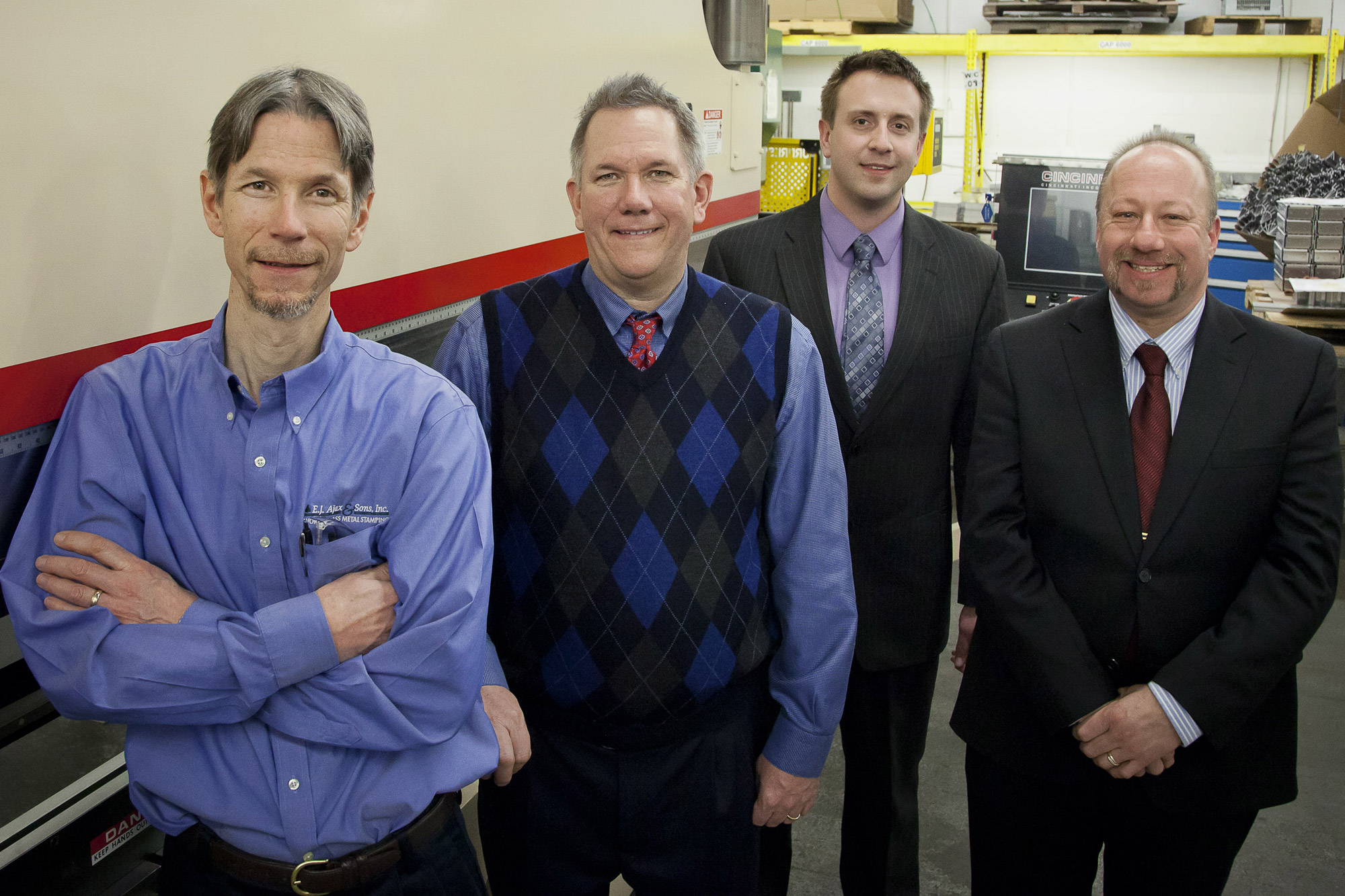

1982 – Tom Ajax (far left), grandson of the founder, joins the company. Tom serves in various capacities at the company until his retirement in 2019.

1984 – Tom’s brother Erick (on Tom’s right) joins the company and also serves in various capacities until his retirement in 2017. Both Tom and Erick continue to serve on the company’s board.

Also shown in this picture are (L-R) current Vice President of Sales and Marketing Don Wellman, who joined the company in 2000, and current President Kent Djubek, who joined in 1990.

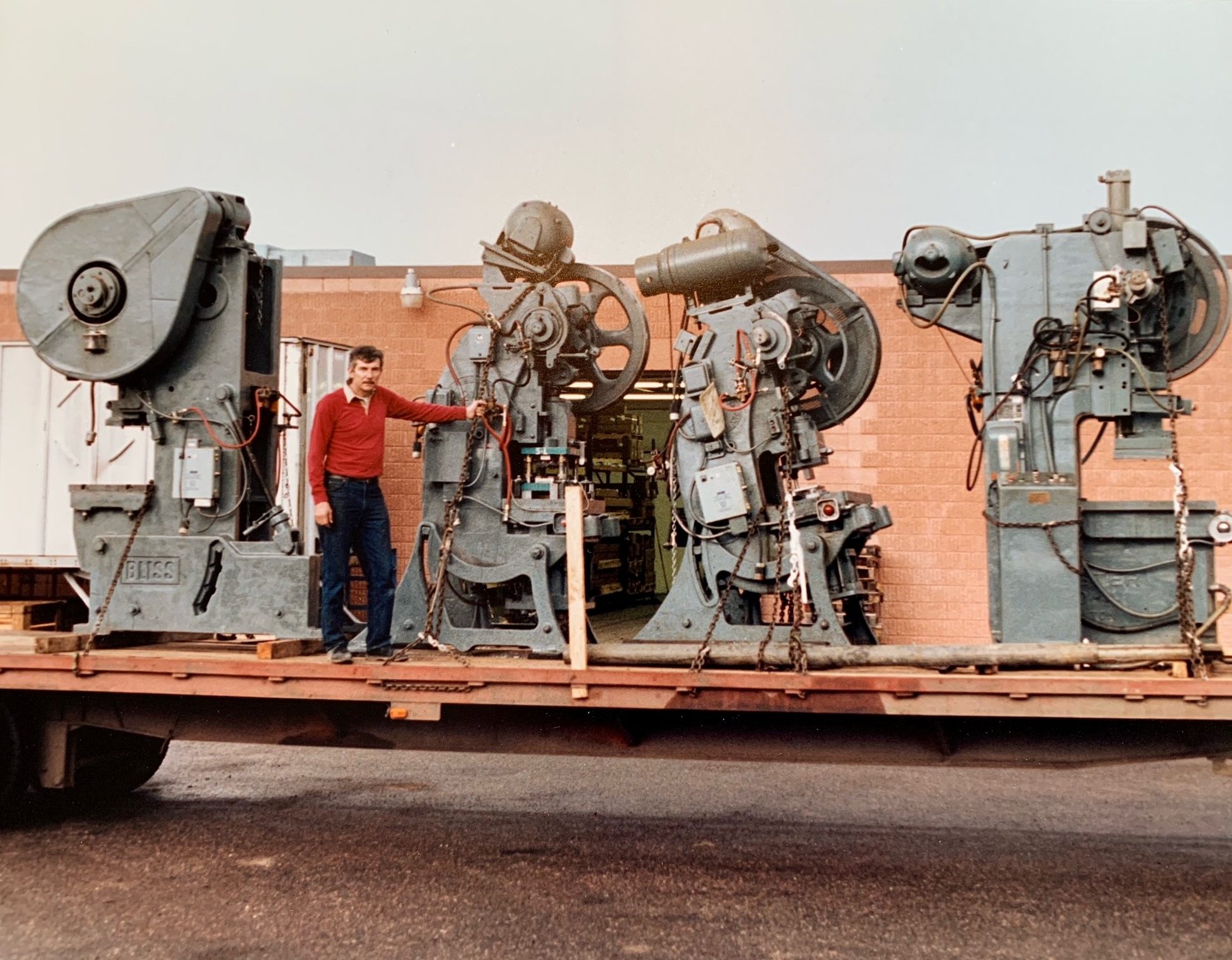

1985 – Sheldon and Barbara leased a portion of the current building and moved in, operating from two production bays. Tom Ajax is appointed company president. In this picture, Sheldon Ajax is shown atop a truckload of stamping presses during the company’s move. Ten years later, the company purchased the entire building and leased unused space to tenants.

1997 – Sheldon and Barbara retire and sell the business to Tom and Erick Ajax. Operating profits are used to pay off the building note without missing a single payment. The brothers embark on a twenty-year period of business investment, modernization, workforce development, and revenue growth.

1993 – Erick Ajax develops the company’s first apprenticeship program with the Minnesota Department of Labor and Industry. He becomes an industry leader and spokesman for workforce development and partners with Minnesota political leadership to help bridge the skills gap. Erick works with area technical colleges and creates the M-Powered curriculum designed to produce skilled manufacturing graduates.

2001 – Ajax purchases a new Minster 200-ton stamping press for $500,000, the largest capital equipment investment in the history of Ajax. This machine adds high-volume progressive stamping to the company’s capabilities, lowering per-part costs to the customer.

2008 – Kent Djubek is appointed company president. Kent’s depth of metal forming experience and breadth of knowledge make him the ideal person for that role. Kent has been with Ajax for more than 30 years.

2008 – The company purchases a new $500,000 LVD Strippit programmable turret press, an extremely versatile programmable press that can produce perfectly formed parts from a variety of metal types at high speed, enabling the company to sell to a new tier of OEM customers.

2012 – The company invests in a new Salvagnini Fiber Laser at a cost of $1 million. This programmable machine uses a computer-controlled beam of light to cut metal sheets into shapes with extreme detail and accuracy.

2013 – Ajax invests in AIDA servo presses at a cost of $500,00 each. Servo technology becomes a game-changer in metal forming, providing exciting new forming capabilities and once again attracting new OEM customers to the company. The company also purchases a 90-ton Cincinnati press brake.

2014 – Ajax receives ISO 9001:2008 certification, with further certification to the new 2015 ISO standard, in recognition of the company’s world-class quality management systems. This is a big moment in the history of Ajax, as more and larger customer accounts become within reach.

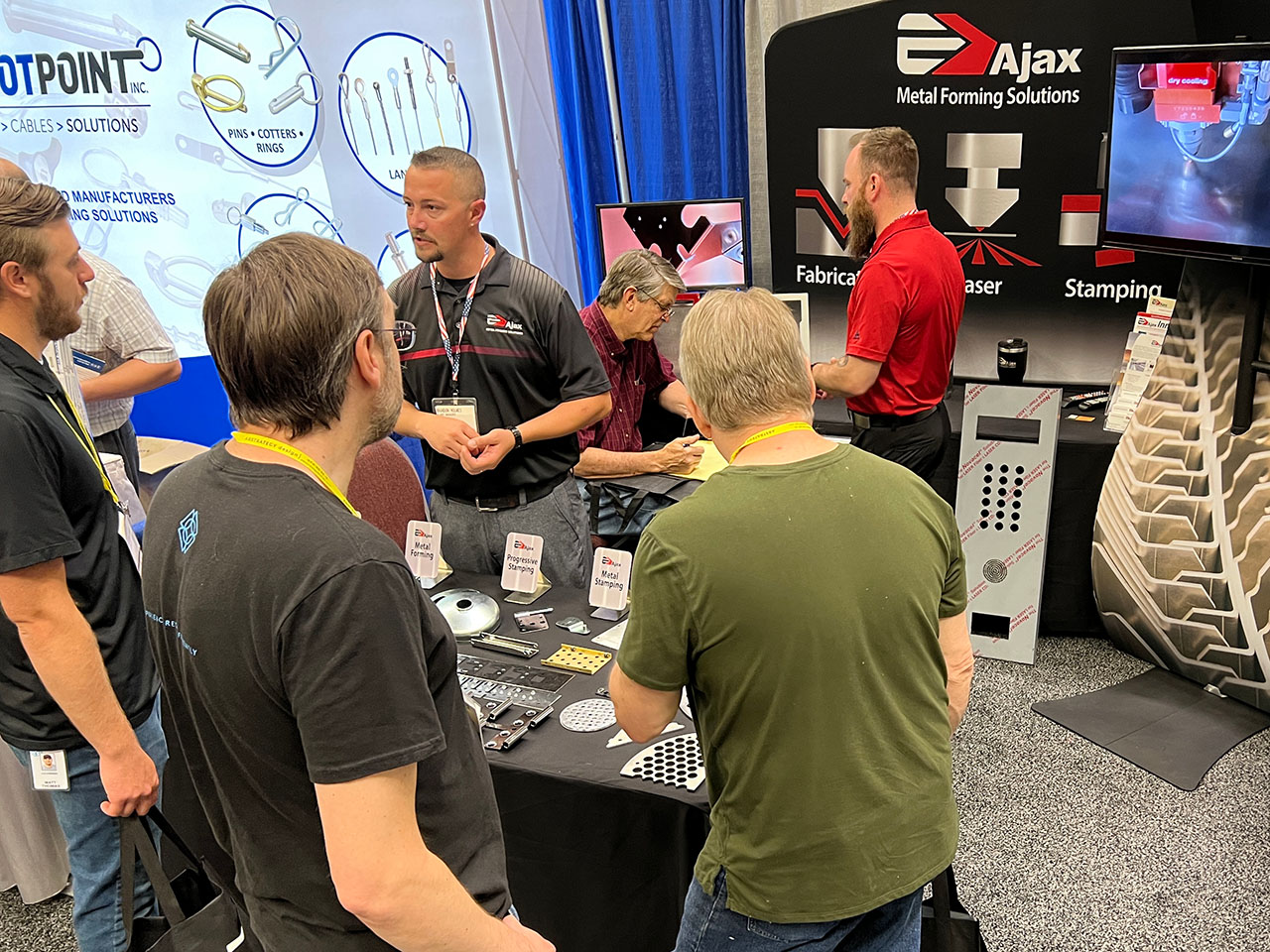

2015 – The company takes over total occupancy of the building as tenant leases expire, bringing production space up to 50,000 square feet. Another LVD Strippit turret press is purchased along with a 175-ton Cincinnati press brake. More emphasis is placed on marketing, including attending trade shows and purchasing a new show exhibit that displays videos, photos, and formed part samples.

2016 – The company adds new technology to the Quality Assurance Lab, including a new FARO measurement arm and scanning probe. This enables the company to perform 3D inspections of the formed parts they produce and to reverse engineer parts that customers provide.

2017 – Ajax purchases an adjacent building, adding 22,000 square feet of space. Erick and Tom sell the company to Heartland Equity Partners. Erick Ajax retires and remains a board member. Tom Ajax stays part-time and then retires in 2019. He also serves as a board member.

2019 – The company purchases a new five-axis Cincinnati Autoform+ press brake with a 14-foot bed, enabling the company to take on very large part production assignments. This massive machine has automatic features that produce perfect parts every time. It represents a new level of productivity at Ajax.

2021 – A second production location opens in Wilson, North Carolina, adding 25,000 square feet of production space. This new location provides sheet metal fabrication solutions to new and existing Ajax customers in the Southeastern United States.

2022 – Recent advancements in industrial robot technology make them far more productive, reliable, and affordable. Ajax purchases a new robotic welding cell featuring a Yaskawa AR1440 welding robot. This investment greatly increases the company’s welding capacity and paves the way for further investment in production automation.