Ajax Adds Southwest U.S. Location

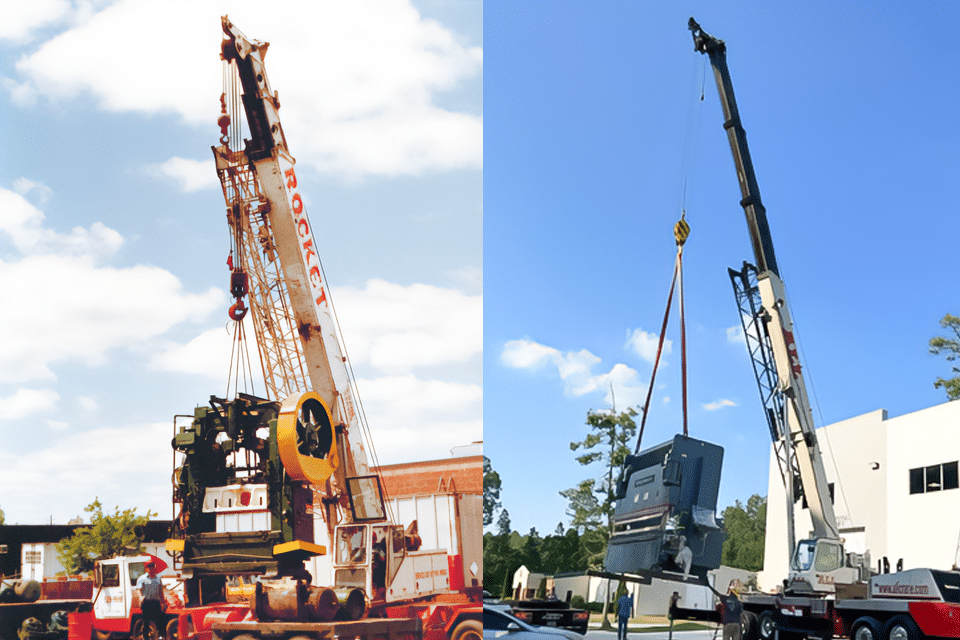

Ajax Metal Forming Solutions is expanding its operations again, this time in Arizona. Ajax ownership has purchased 30,162 square feet of space at 4646 S. Overland Drive in Tucson. The full expansion over five years will add 20 jobs, primarily in operations and manufacturing, with an economic impact of $22 million. The solar-powered facility is scheduled to become operational in Q3 2024.

“Tucson checked all the boxes for us,” said Ajax President Kent Djubek. “Proximity to our customers, access to raw materials, good transportation infrastructure, and a superior technical workforce. We’re especially looking forward to welcoming colleagues on board from the University of Arizona and Pima Community College,” he said.

“Ajax’s decision to expand their operations to Tucson/Pima County is good news for Southern Arizona’s economy,” said Rex Scott, District 1 supervisor and vice chair of the Pima County Board of Supervisors. “Pima County has a lot to offer businesses, from a pro-business environment to a talented workforce and exceptional quality of life, and we’re glad to have companies like Ajax bringing more jobs and investment to our region.”

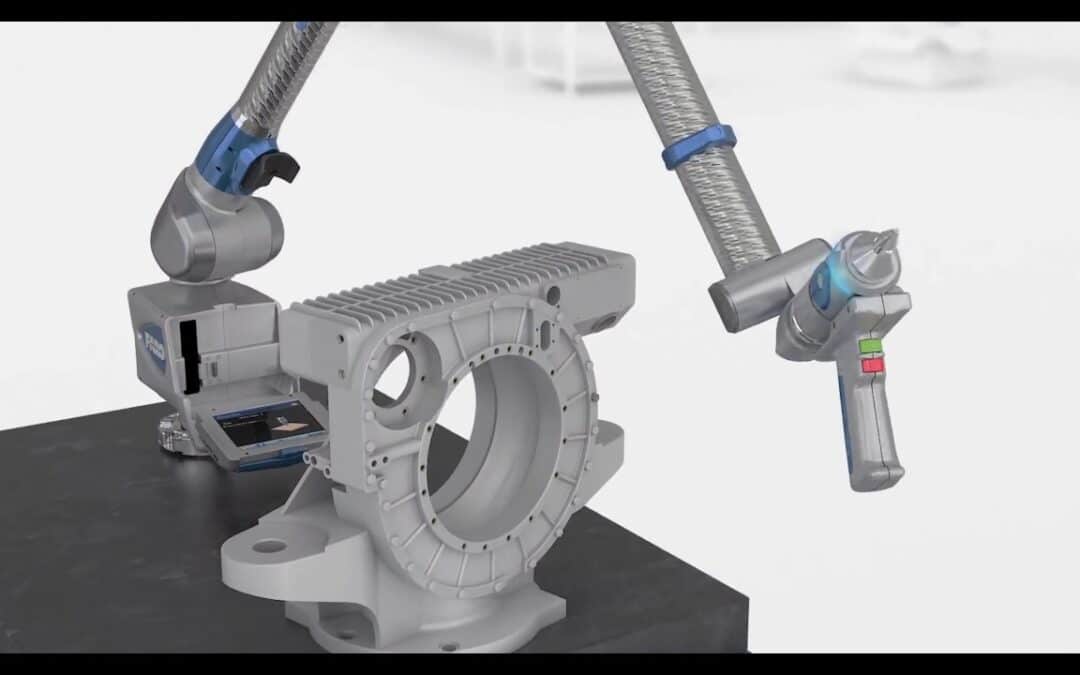

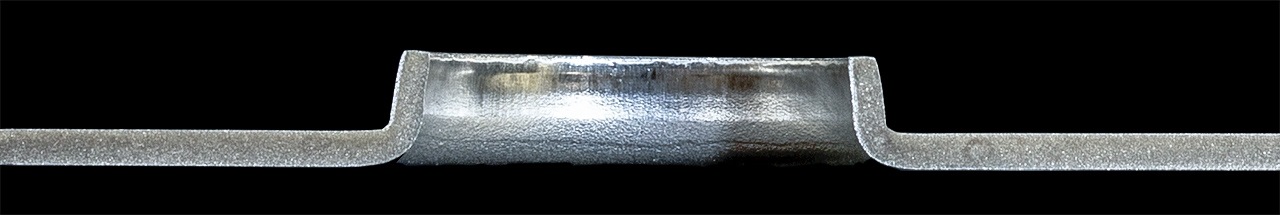

“The decision by Ajax to expand its operations in Southern Arizona, including investments in the latest robotics, sustainability, machinery, and software applications, really validates that our position as an advanced manufacturing center is strong and growing,” said Joe Snell, president & CEO of Sun Corridor Inc. “Ajax is an incredible company whose presence benefits us greatly.”