Progressive Stamping With Hardware Insertion

The Situation

Tooling expertise, a wealth of machinery, and trained press operators. These are the basic requirements for progressive stamping success.

Add hardware insertion to the mix, and things become more complex. You’ll need pneumatic actuators and servomechanisms that work in perfect synchrony with the die set to form-in the hardware on the fly.

There’s more. Customers expect spot-on quality compliance and cost-efficient production. Those, coupled with reliable logistics, are progressive stamping capabilities that only the best metalformers offer.

The Challenge

A customer asked Ajax to produce u-style fastening clips in large quantities with excellent cost efficiency. The clips would have regular exposure to the elements, so stainless steel was specified.

The customer’s design required an inserted nut with multiple threads for reliable engagement and a tight bend to keep the clip firmly in place. But forming needed to occur after the hardware was inserted. If the part was formed first, the insertion hole would not be accessible.

The customer trusted Ajax to recommend the solution, source the right material, build the die set, and produce perfect parts.

The Success

The Ajax team combined tooling, pneumatics, and sensors to create a stamping line that neatly trimmed the inbound steel coil, inserted the hardware, and formed the part, all in a single process.

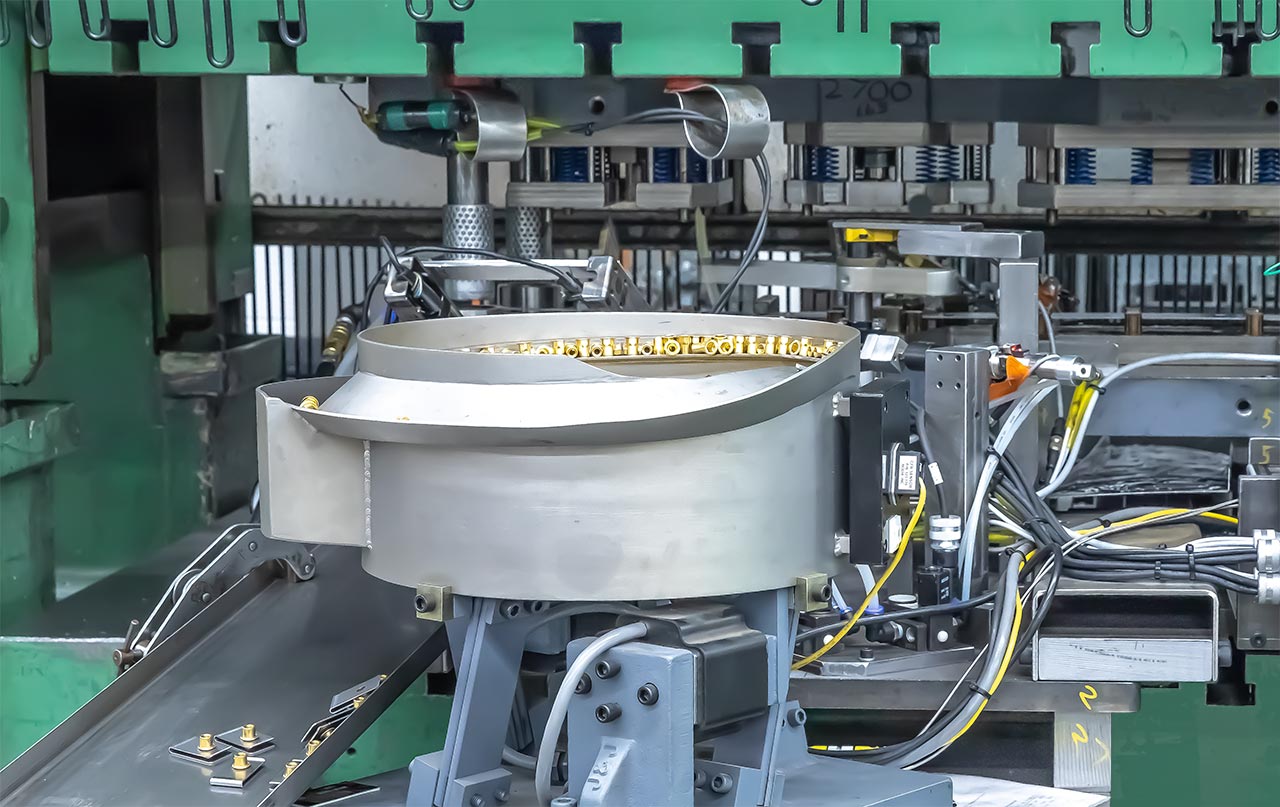

A vibratory bowl fed the hardware through a track to a pick-and-place spindle. The spindle dropped the hardware into a die slot. The hardware was then compressed into the part on the subsequent hit.

With this solution, Ajax applied multiple operations with just one die set. The result was more parts per hour, far greater cost efficiency, and a near-perfect quality compliance record.

With in-house tooling, updated machinery, and generations of experience in progressive stamping and metal fabrication, Ajax delivers quality-compliant parts, competitive pricing, and responsive customer service. Call Ajax sales engineering at 763-277-7760 to discuss your next project. Please visit our progressive stamping page for a video of this hardware insertion operation.

Hardware from a vibrating bowl feeds the hardware insertion arm.

The insertion arm loads hardware from the bowl and sets the hardware into the part before forming.