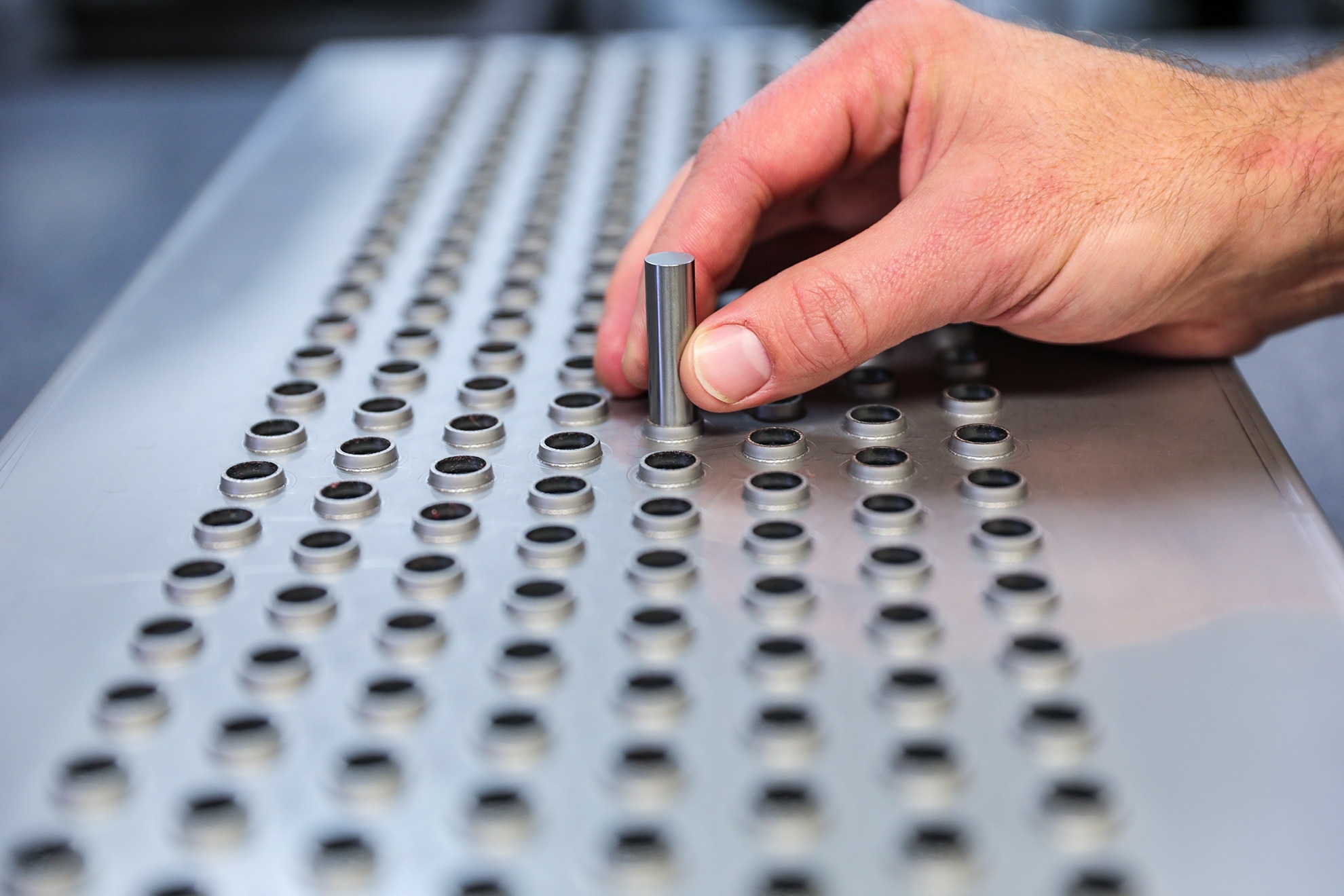

HVAC Header Plate With Perfect Extrusions

Redesigning a residential header plate project from a turret press to progressive metal stamping resulted in $50,000 in annual savings and a new relationship with a satisfied client. Progressive metal stamping made from engineered aluminum alloy of slit coil eliminated the scrap that the turret press left behind. The progressive stamping reduced both scrap costs and extra labor, and produces the part 2 to 3 times faster than the turret press.

Header Plate Project Specifications:

- Product Name: Residential HVAC Header Plate

- Project Scope: Process redesign, material and labor cost-out

- Design Work: Progressive tooling, manufacturing process

- Product Description: Mass volume progressive HVAC stamping

- Capabilities Applied/Processes: Convert turret press to fully progressive coil-fed stamping. Cost-out scrap and labor expense.

- Tightest Tolerance:.002″ (Hole location)

- Material Thickness:.050″

- Material Used: 3003 aluminum with 1.5% zinc

- Material Finish: None

- Industry for Use: Residential HVAC

- Volume: 30,000 parts annually

- Lead Time: KANBAN

- Delivery Location: Southern U.S.

- Standards Met: 200 hours of salt spray testing; RoHS and REACH

Get Your Fabrication Project Quote Underway!

Ajax sales engineers are available to help you determine the most productive and cost-effective solution for your metal forming project.