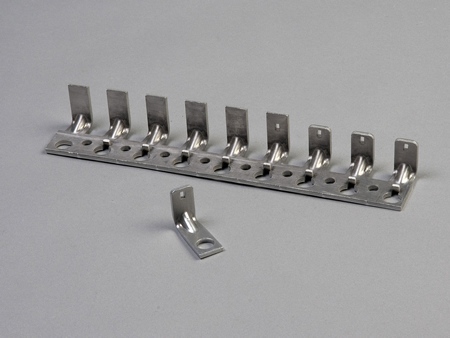

Pressure Safety Lock For Small Appliances

Our customer came to Ajax because they had problems holding tolerances on an aluminum bracket with a square notch. This part is used as a safety component on a consumer small appliance, so the material and tolerances needed to be perfect to avoid user injury. Ajax designed a strengthening gusset that lets the part work-harden, while maintaining dimensional integrity within .5°.

When the customer moved manufacturing to China, they retooled everything except our part. The offshore operation couldn’t meet the functional requirements. As a result, we didn’t lose a customer, we gained a market. Volume increased from 50,000 parts per year for the U.S. market to nearly a million parts per year globally.

| Tightest Tolerance | .005 inch and .5° +/- |

| Material Thickness | .125 inch |

| Material Used | 5052 H34 aluminum |

| Material Finish | N/A |

| Industry for Use | Consumer appliance |

| Volume | 1 million annually |

| Delivery Time | Kanban |

| Standards Met | U/L |

| Product Name | Pressure Safety Lock |

| Project Scope |

Product re-design; material selection; rapid prototyping; production tooling Design Work, Rapid prototyping; production tooling |