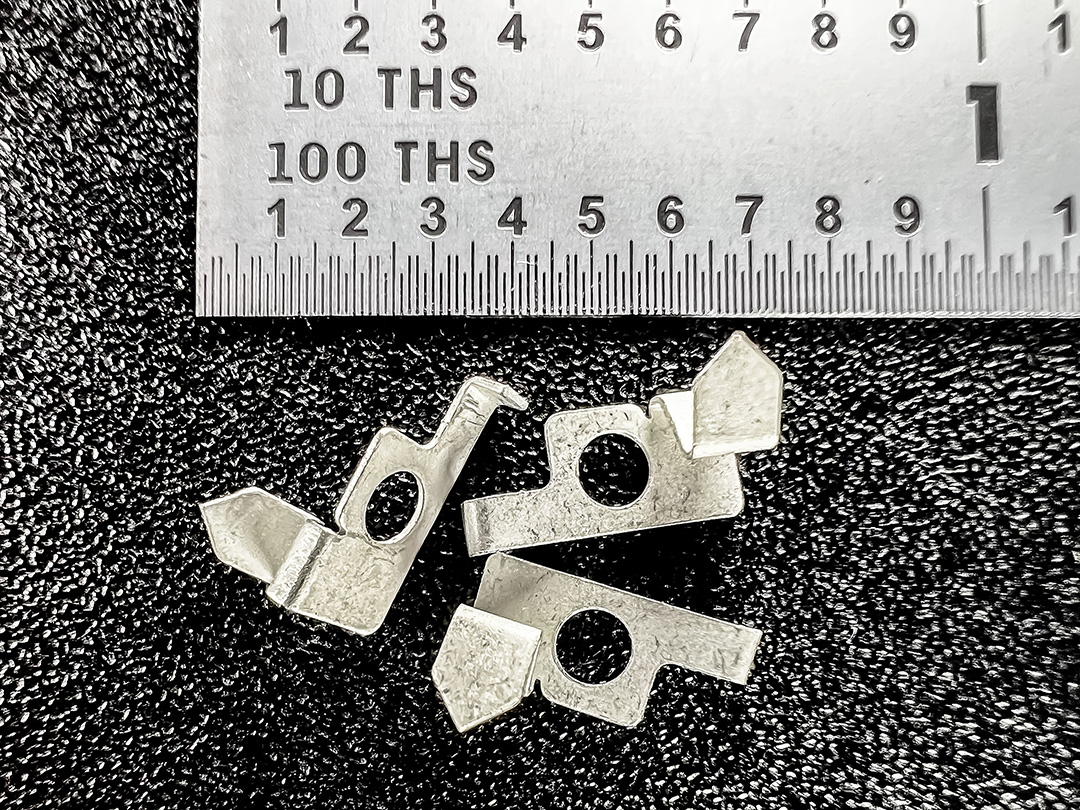

Tiny Progressive-Stamped Beryllium Copper Grounding Bracket

This bracket is so tiny that we designed a vacuum system to remove it from the progressive die. It’s made from beryllium copper that is heat-treated and tin-plated. The part has to provide enough spring to ground a circuit to the enclosure. The customer tried outsourcing, but the Chinese manufacturer couldn’t produce the part to print.

Ajax produced the part to spec, and we use a Minnesota-based source for heat treating and plating. The result: the customer gets the desired quality and saves operating expenses due to a streamlined supply chain.

Specifications:

- Product Name: Grounding bracket

- Project Scope: Material selection; strategic sourcing

- Product Description: Grounding bracket for circuit board

- Capabilities Applied/Processes: Progressive stamping

- Tightest Tolerance: .004 inch +/-

- Material Thickness: .010 inch

- Material Used: C17200 BeCu

- Material Finish: Heat-treated; tin-plated

- Industry for Use: Electronics

- Volume: 23K annually

- Delivery Time: Kanban

- Delivery Location: U.S.

- Standards Met: Customer supplied print and 3D model

- Product Name: Grounding bracket

- Project Scope: Material selection; strategic sourcing

Let’s Get Your Project Underway!

Ajax sales engineers can help you determine the most cost-effective solution for your stamping and sheet metal fabrication project.