Fiber Optic Laser Cutting

Fast, accurate, and cost-effective.

An Ajax fiber laser cutting head in action.

Unrivaled Precision and Quality

Ajax was an early adopter of fiber optic laser cutting. We knew that customers would want precise, high-quality cuts with clean, smooth edges that require little or no post-processing beyond deburring. Here are just a few of the manufacturing benefits:

- Fiber optic laser cutting machines can cut metals at much faster speeds compared to traditional cutting methods, increasing productivity and reducing lead times

- Lasers have high energy efficiency, converting electrical energy into laser energy with high efficiency.

- The precision of lasers enables efficient nesting and maximizes sheet utilization, further reducing material waste.

- Lasers prioritize operator safety with features like enclosed cutting areas and automatic shutdown mechanisms, providing a safer work environment.

Fiber optic laser cutting at Ajax is an efficient way to cut blanks from wide variety of materials, including:

- Stainless steel

- Carbon steel

- Aluminum

- Copper

- Brass

- Titanium

- Even some exotic metals

Maximum material thickness will depend on material type. Consult with an Ajax sales engineer to determine the ideal material type for your project.

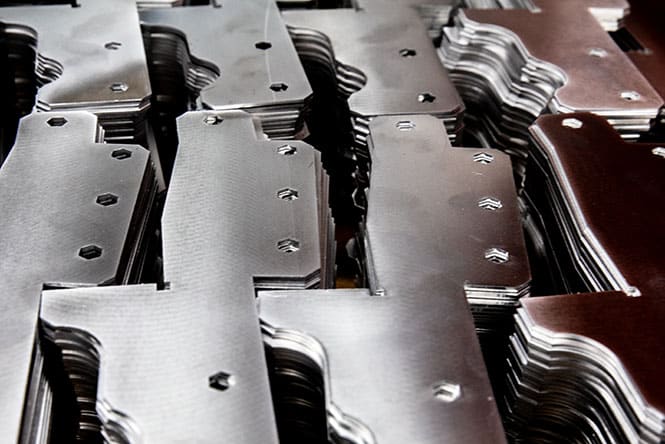

Ajax fiber optic lasers can cut large sheets of stainless steel, copper, aluminum, and many other metals and alloys.

Fiber Optic Laser FAQs

When Is Fiber Laser Cutting A Good choice?

Speed and cut quality are the two primary reasons to choose fiber lasers. These machines cut 2–5 times faster than traditional shearing, especially when working with thin metals (under 6mm), making lasers a very efficient choice. Also, the small beam diameter and focused energy delivery offer extremely fine and accurate cuts. This results in tighter tolerances, smoother, cleaner edges, and minimal post-processing steps such as deburring. Fiber lasers excel at cutting complex, rounded patterns and shapes, which would be impossible with straight-cutting shears.

Fiber lasers are ideally suited for high-volume, automated production environments like Ajax. Their reliability, speed, and ease of integration make them ideal for unattended operation, which reduces labor costs. Fiber laser systems can also perform etching, ideal for customers who need part traceability.

What Materials Should Not Be Cut With Fiber Optic Lasers?

Coated metals, such as galvanized steel, are not ideal for fiber lasers due to fume emissions and operator safety issues. Layered or composite metals may require special considerations.

What Finishing Processes Does Ajax Provide?

Ajax enhances stamped parts through various metal finishing services, including powder coating, anodizing, electro-polishing, and plating. Additionally, Ajax offers comprehensive product assembly using specialized fastening hardware and robotic welding. Ajax also provides kitting services, enabling efficient and economical downstream assembly.

How Does Ajax Provide Quality Assurance?

Quality assurance is integral to Ajax’s stamping operations, ensuring every part meets stringent standards. Ajax employs comprehensive inspection methods—from precision hand-held measurements using digital micrometers and calipers to advanced laser scanning technologies. These practices ensure dimensional accuracy, surface integrity, and material consistency, safeguarding against defects and reinforcing Ajax’s reputation for quality and compliance.

Progressive metal stamping operations incorporate rigorous quality controls, utilizing techniques like laser measurement, visual inspection, and in-line sensor technologies. These systems swiftly identify and correct anomalies, ensuring consistent product excellence.

Ajax also prioritizes environmental sustainability, actively reducing scrap, recycling metal waste, and optimizing energy efficiency throughout the stamping process. By designing processes and dies that minimize waste and implementing comprehensive recycling programs, Ajax contributes to sustainability efforts and achieves valuable cost savings.