Serving These Industries

With These Advanced Capabilities

5

Five good reasons to choose Ajax as your metal forming partner.

Latest Ajax News

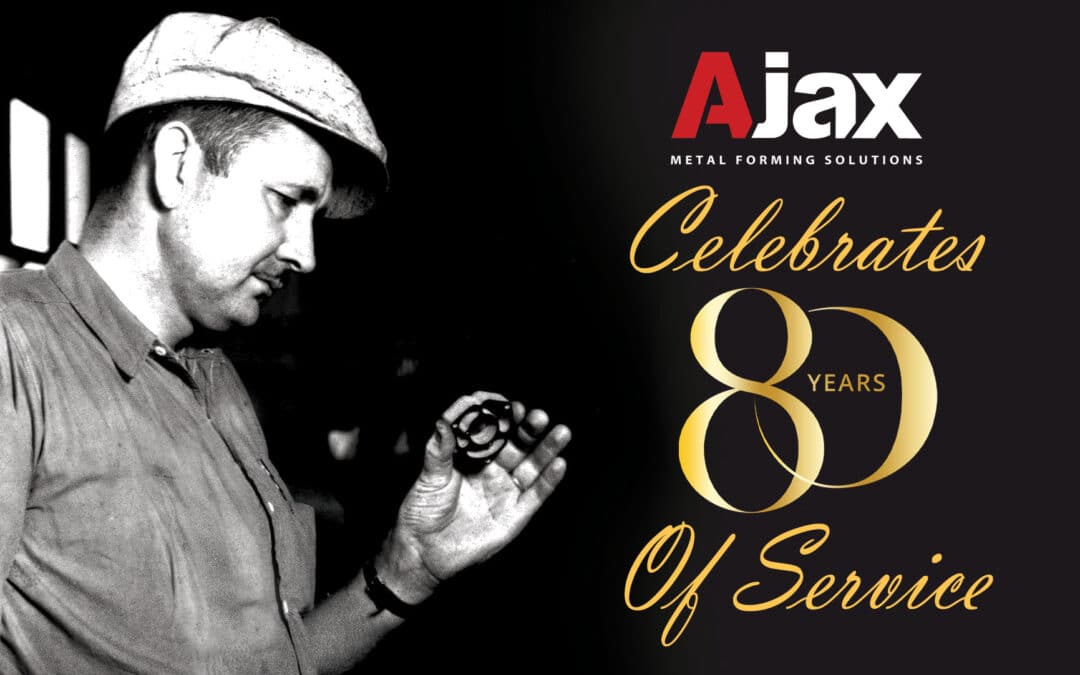

Ajax Celebrates 80th Anniversary

2025 marks 80 years of service at Ajax, another milestone our relentless pursuit of innovation, manufacturing excellence, and exceptional customer care. Everyone on the Ajax team eagerly anticipates the continuation of our proud legacy as we provide stamping and sheet metal fabrication services to valued customers for decades to come. Visit our History page for a timeline and photo archive of the Ajax journey.