Serving These Industries

With These Advanced Capabilities

5

Five good reasons to choose Ajax as your metal forming partner.

Latest Ajax News

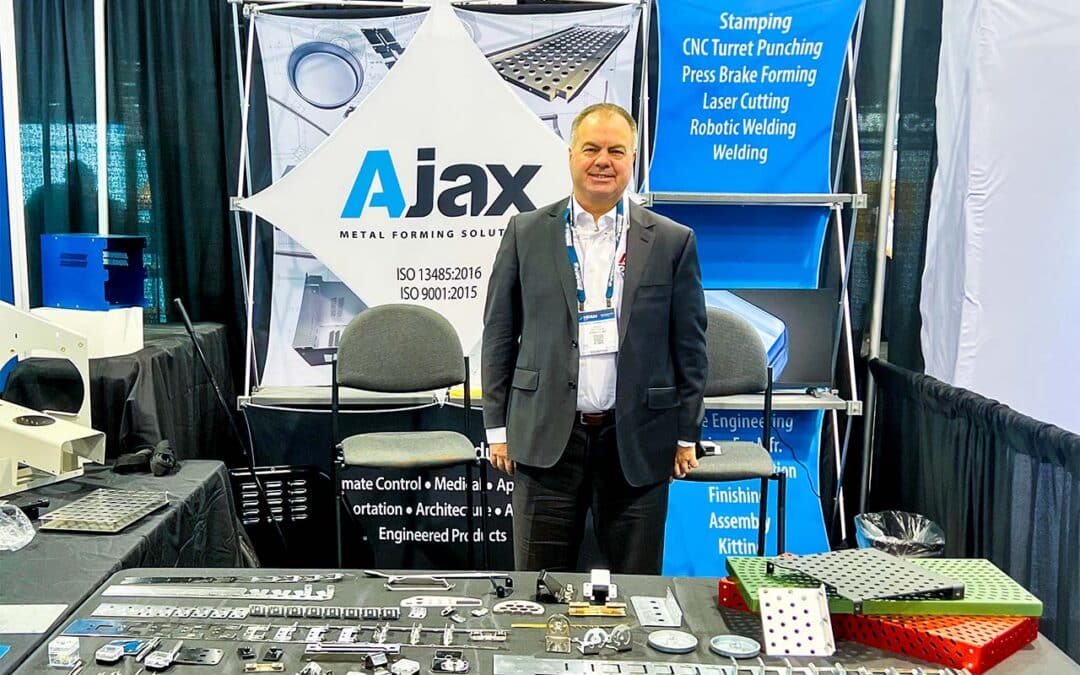

MD&M Thanks

Ajax Business Development Manager Mark Davidson at the Ajax booth at MD&M in Anaheim, California. Thank you to everyone who visited with the Ajax metal forming crew at MD&M 2026 in Anaheim, California. This completes our third year at this show, and we're delighted to report that the event was a big success. Looking forward to seeing you there next year!