Serving These Industries

With These Advanced Capabilities

5

Five good reasons to choose Ajax as your metal forming partner.

Latest Ajax News

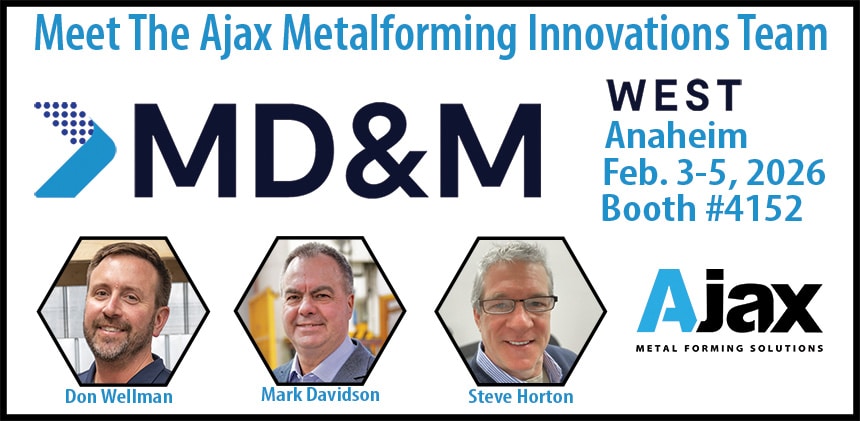

Ajax At MD&M

We invite you to visit the Ajax metal forming crew at MD&M 2026, February 3–5, at the Convention Center in Anaheim, California. It's the medical device industry’s largest annual gathering! Ajax sales engineers will be on hand to provide insight on best practices for stamping and fabricating metal parts and assemblies for medical devices.