Progressive Stamping

The Intersection of Efficiency and Quality

Progressive Stamping Solutions To Meet Your High-Volume Needs.

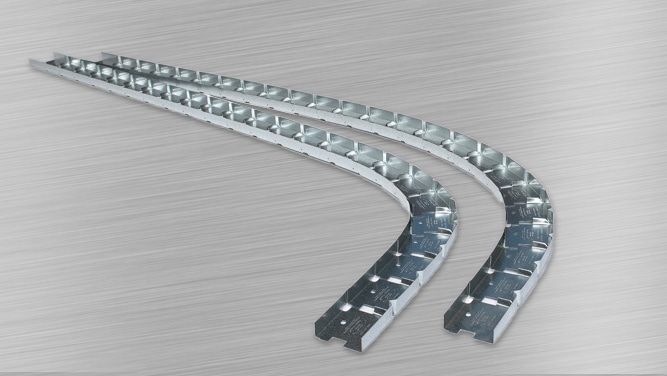

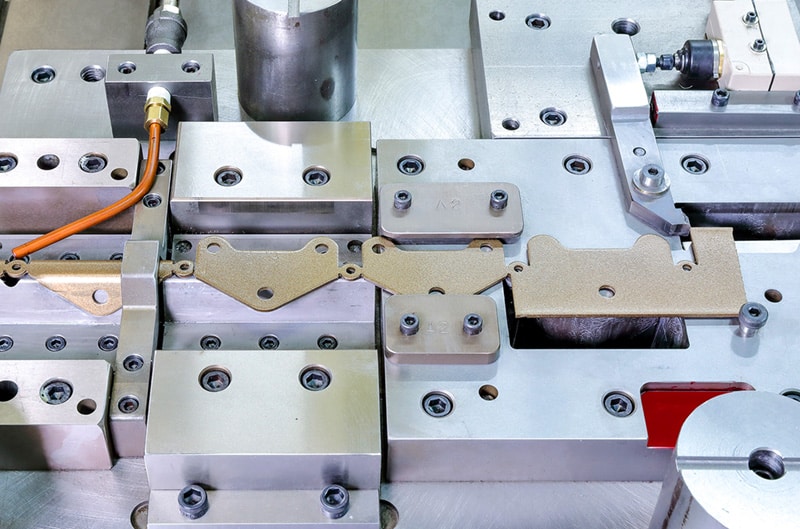

Progressive stamping is a highly-efficient process that can produce complex parts at scale with uniform quality. Material is continuously fed, enabling the operator to maintain a fast production rate with relatively little scrap.

Better Solutions, Better Results.

Ajax designs stamping solutions to meet or exceed our customers’ production goals, even those with tight tolerance requirements. Modern equipment enables more automation at each step in the process and keeps our operator safety record among the highest in the industry. Ajax sales engineers have vast experience designing stamping lines that produce parts reliably and keep our customers’ production lines humming.

Progressive stamping is ideal for long-run, high-volume parts, like these parts that require brass, bowl-fed hardware insertion.

Related Stamping Services

Deep Draw & Servo Stamping

Deep drawn stamping produces hollow vessels, like a deep pan, bowl, or cup-shaped part. Often the metal is heated or oiled to aid the process.

Design For Manufacturing

DFM goals include the fewest possible process steps, timely materials purchase, lower costs, higher part quality.