Metal Stamping

Progressive, deep drawn, servo, high volume, Ajax does it all.

Providing a Complete Metal Stamping Solution.

Ajax produces tight-tolerance stamped metal parts using several types of machinery and processes, all chosen and designed specifically to meet customer specifications. Capabilities include progressive stamping, deep-drawn stamping, servo stamping, and more.

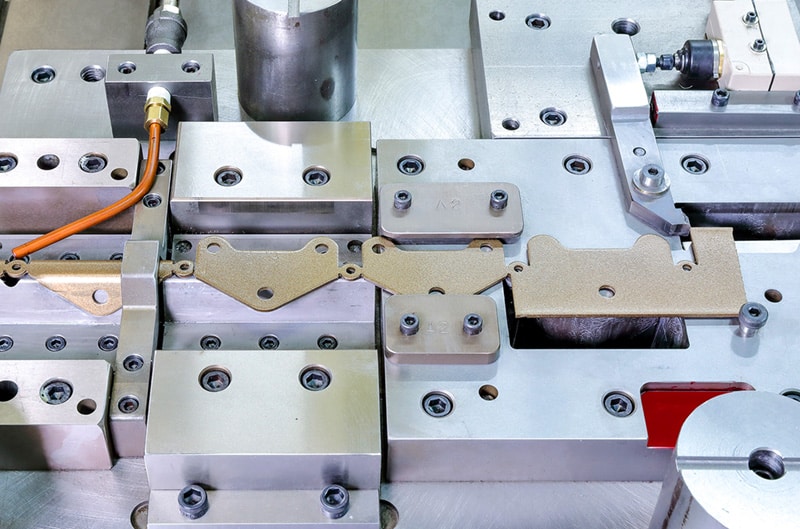

To continually improve die set performance and keep processes efficient, Ajax maintains a complete in-house tooling department. In-house tooling also speeds project start-up, and stands ready to repair or replace worn die set components.

Just The Right Stamping Solution To Meet Your Requirements.

Metal stamping is a core competency at Ajax. Our sales engineers have the experience and training to custom-design stamping processes. They can design the most efficient part production solution, yielding highly-compliant parts with minimal scrap.

Whether your needs include high-volume, short-run, tooling, or prototyping, our design-for-manufacturing experts can ensure that your project moves ahead efficiently and on-spec.

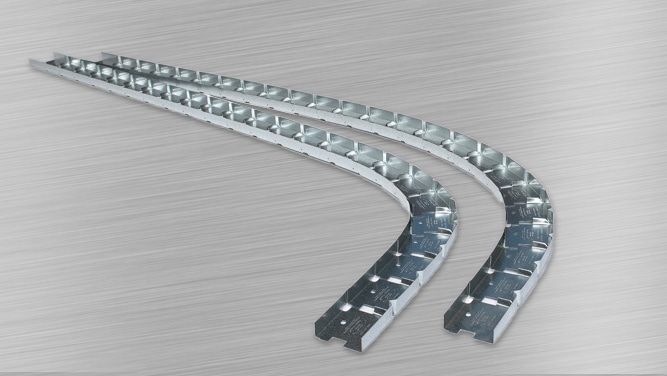

Some customers opt for progressive stamping when the project call for long-run, high-volume parts, like these parts that require brass, bowl-fed hardware insertion.

Related Stamping Services

In-House Tooling

Ajax offers an in-house tooling team that can design, build, or repair stamping tools, progressive die sets, or modify a customer’s die set to meet a new part requirement.