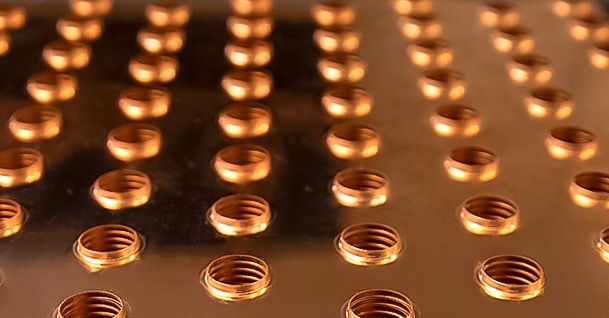

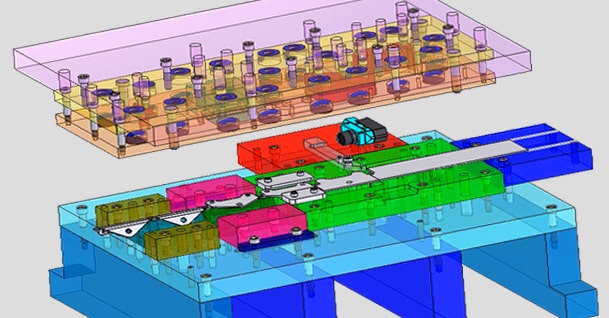

Metal Stamping and Sheet Metal Fabrication

Ajax Metal Forming is your trusted provider of world-class stamping, fabrication, fiber optic laser cutting, welding, and more.

Industries Served

Architecture

Agricultural Equipment

Engineered Products

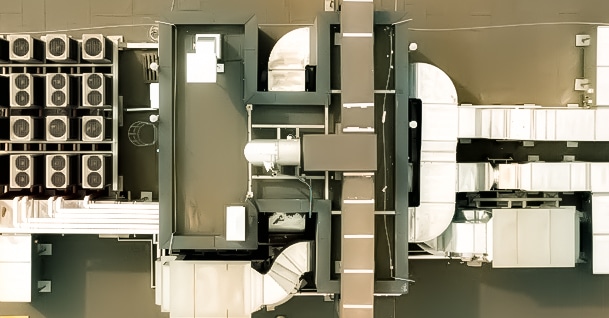

Sustainable Manufacturing

Sustainable manufacturing means more than recycling. It requires examination of every phase of the manufacturing process, from materials to machinery to logistics and more. Find out how Ajax is making sustainable manufacturing work for customers, employees and communities.