Providence Academy’s FIRST Robotics Team – #4511 – Power Amplified – successfully concluded their 2021 season! Although challenged by the pandemic, the 2021 team produced a very advanced robot. Here’s the online recap: https://bit.ly/3tZeWkY.

A little background: Michael Plucinski, Providence’s FIRST Robotics Team Instructor, contacted Ajax in early February and explained the team’s need for specialized, laser-cut parts for their 2021 robot. The Providence robot is designed to auto-navigate along complex paths and accurately launch game pieces at a target.

Consistent with the company’s community-service mission, Ajax jumped at the chance and provided expertise, labor, and materials to the team free of charge. Ajax Sales Engineer Jayson Marcott administered the project while the Ajax production team formed the parts on a Salvagnini fiber optic laser and ran them through a deburring machine.

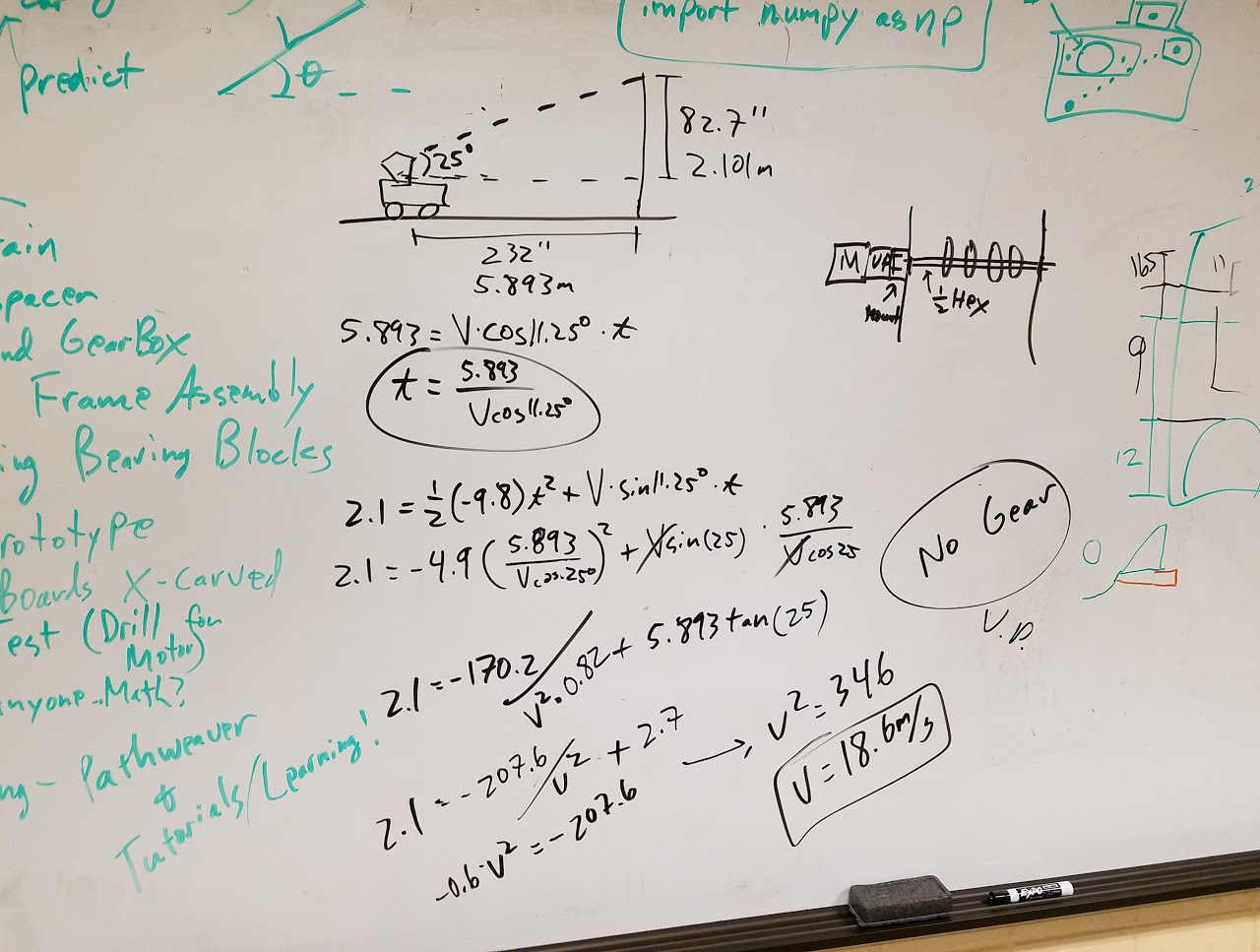

The photo below shows a small portion of the calculations that went into the robot build. Bear in mind that Providence is a K-12 institution. Needless to say, these young people are working and learning at a very high level.